Physical Vapor Deposition (PVD) coatings are widely used in the automotive industry for various applications due to their excellent properties such as wear resistance, corrosion resistance, and decorative finishes. Here are some common uses of PVD coatings in the automotive sector:

Protective Coatings:

PVD coatings are used to protect automotive components from wear, corrosion, and abrasion. For example, coating on engine components, piston rings, and bearings can enhance their durability and lifespan.

Decorative Finishes:

PVD coatings provide a wide range of colors and finishes, making them ideal for decorative applications on automotive trim, badges, wheels, and other parts.

Improved Fuel Efficiency:

By reducing friction and wear on engine components, PVD coatings can contribute to improved fuel efficiency in vehicles.

Enhanced Performance:

PVD coatings can be used to reduce friction on critical components such as gears and transmission parts, leading to better performance and reduced maintenance requirements.

Eco-friendly Solutions:

Some PVD coatings are environmentally friendly compared to traditional chrome plating methods, making them a preferred choice for automotive manufacturers aiming to reduce their environmental impact.

Increased Durability:

Components coated with PVD layers exhibit increased resistance to scratches, chemicals, and harsh weather conditions, leading to longer-lasting automotive parts.

Reduced Weight:

PVD coatings can be thinner than traditional coatings like electroplating, reducing the overall weight of components and contributing to lightweighting efforts in the automotive industry.

Overall, PVD coatings offer a versatile and effective solution for enhancing the performance, appearance, and longevity of automotive components, making them a popular choice across the industry.

Please learn below and find out what Royal Tech can provide you:

1. Vacuum Metalizing Equipment

A: Automotive Lighting Reflectors - RTEP/RTEP-HMDSO (PVD+PECVD)

B: Exterior & Interior Trims, handles- RTSP

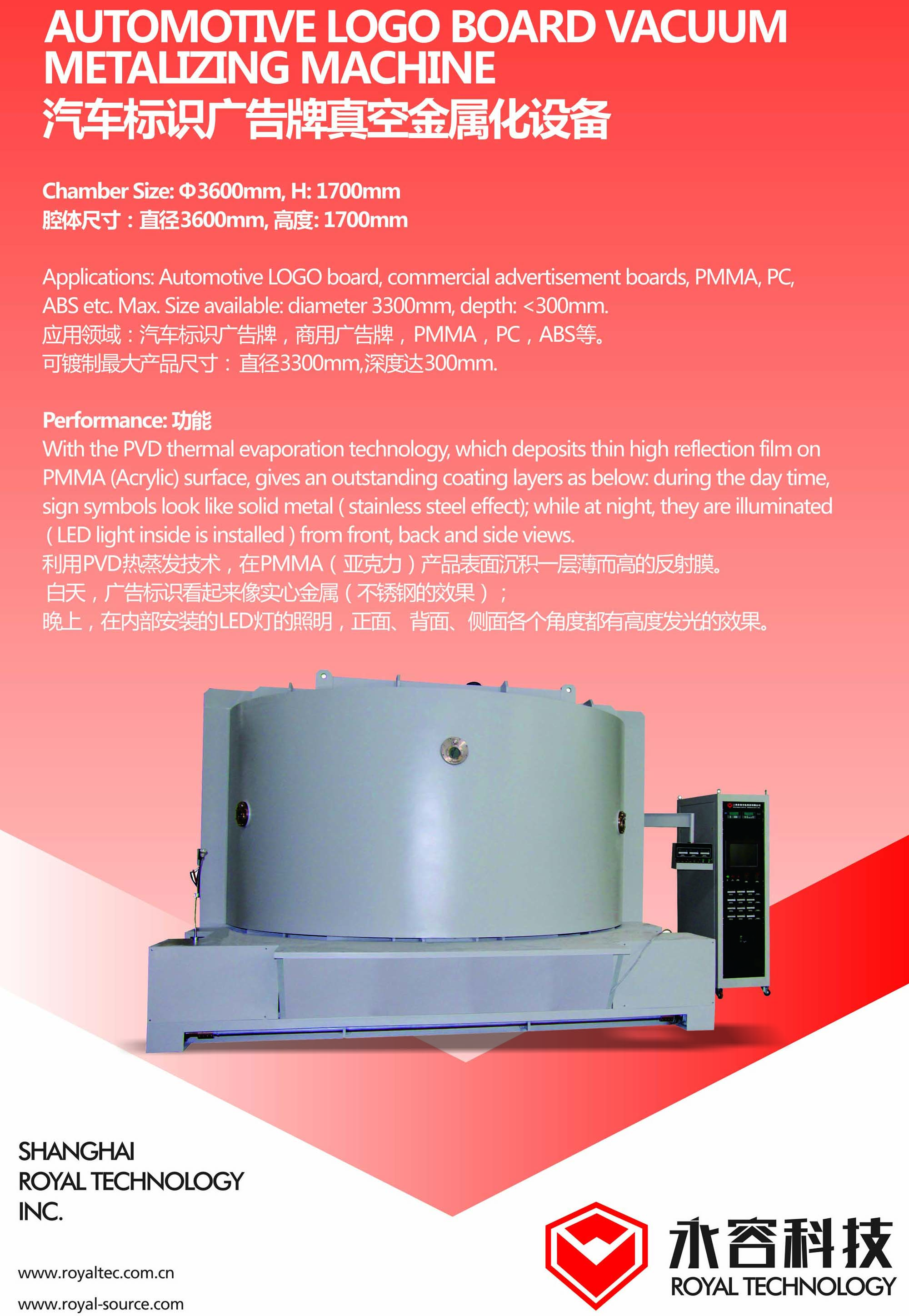

C: Automotive LOGO LED board- RTEP

D: Bezels and bumpers-RTEP

2. PVD Hard Chrome Sputtering System

A: Car Wheels- RTSP

B: Car Mirrors- RTSP-PLUS

Royal Tec has developed S, M, L batch standardized models to satisfy our customer’s demand.

3. Hydrogen Fuel Cell Sputtering System

Disruptive innovative technology in the FCEV industry - RT1200-FCEV