Technical Specifications

Royal Technology provides both Vertical and Horizontal models of Large Size arc coating machines.

| Description | Vertical | Horizontal | ||

| RTAC1836 | RTAC2040 | RTAC2080 | RTAC2270 | |

| Standard Applications |

Stainless Steel Sheets: 1000*2000mm、1219*2438mm、1500*6000mm、1800*6000mm

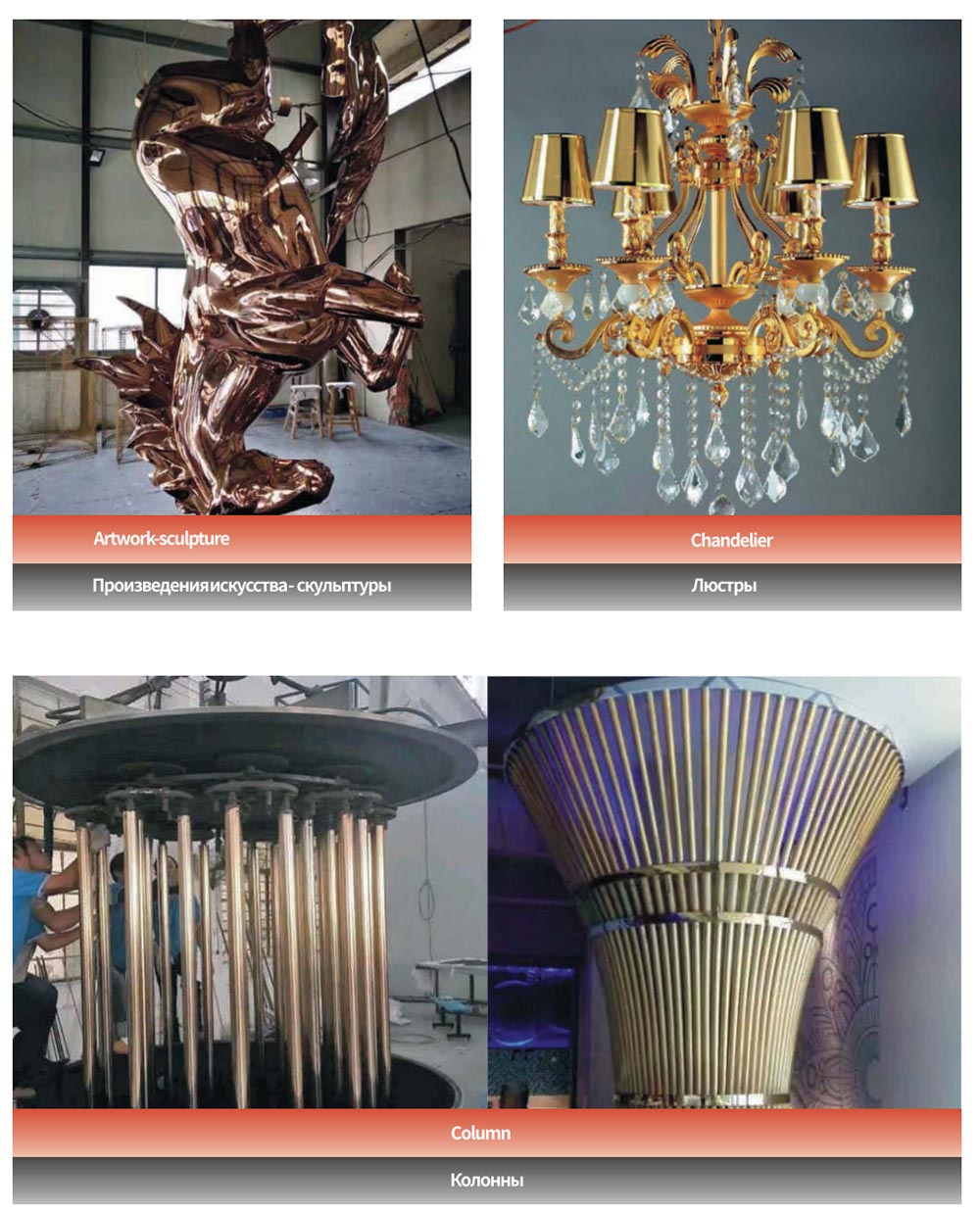

Stainless Steel Pipes size: diameter 15mm ~ 300mm, length up to 6000mm Crystal Chandelier, Glass Lighting Stainless Steel Gate/Wall/ Fence/windows Ceramic Tiles Stainless Steel Furniture: chair, table, desk, bed, display cabinet, clothes hooks, sculpture. Others: windows, walls, hotel, KTV, Bars, elevator panels for aesthetic surface finishing. |

|||

| Key Features |

1.High throughput up to 10 cycles per day;

2.Solid whole structure system for more than 30 years life time; 3.Compact design and with easy access for upgrading and maintenance work. 4.Fully Automation, PLC+Touch Screen, one-touch operation and control system. 5.High efficiency with less power consumption, max. 50% production cost saving. 6. Workshop layout plan support is available from RoyalTech. |

|||

|

Deposition Chamber

(mm) |

φ1800 * H3600 | φ2000 * H4000 | φ2000 * L8000 | φ2200 * L7000 |

| Total Power (kw) | 120-300 | 120-350 | 200 | 200 |

|

Circular Arc Cathode (sets) |

24-36 | 40-60 | 50~60 | 50~60 |

| Rack and Jig System | Planetary , central driving or integrated in one machine | |||

|

Pulsed Bias Power

(KW) |

60 | 60 | 70 | 70 |

| Heating System | Controllable and adjustable from room temperature to 300°C | |||