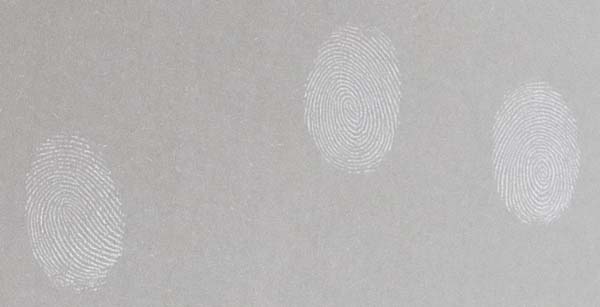

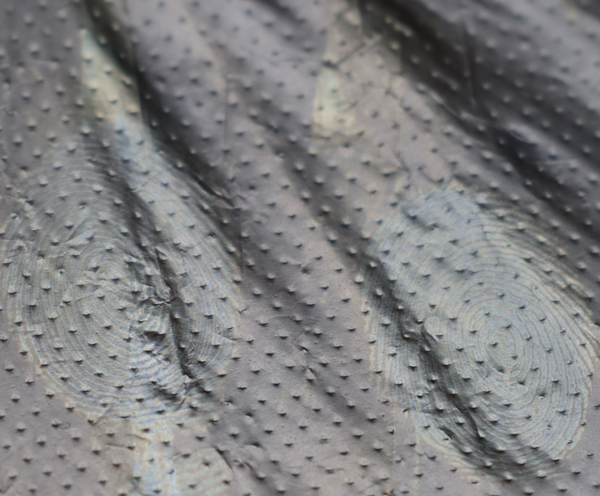

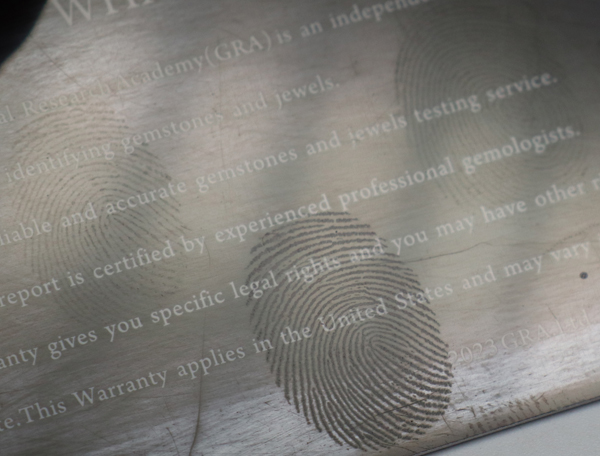

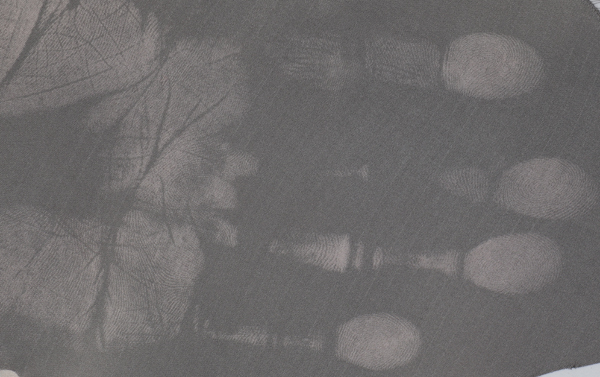

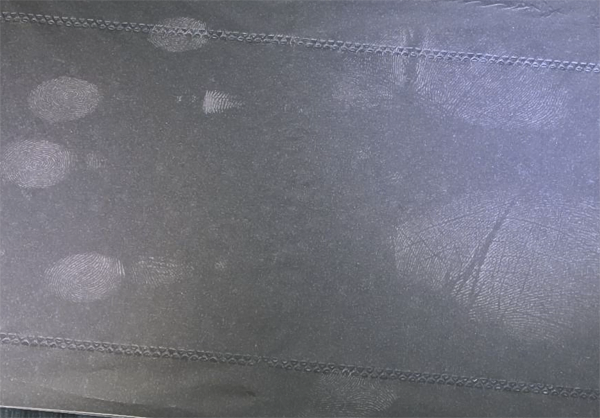

RTEP0405-FORENSIC machine is developed and applied with the forensic industry. It is used to process various ranges of exhibits from plastic, metals, steel, polymer, paper, fabric or glass materials, and can deposit metal films like silver, gold, zinc, aluminum to generate high imaging finger marks on criminal objects. A huge range of non-porous, semi-porous and porous items e.g., flexible plastic packaging, paper, plastic bottles, cell phones, glass, fabrics, firearms, fired ammunition, knives, thermal paper, wood, currency, IEDs, latex gloves etc. can be processed.

In the year of 2024, Royal Technology has upgraded the system to Generation III - RTEP0405-FORENSIC model.

More advanced performances are benefit the end user.

HIGHTLIGHTS

Environmentally Friendly

Energy Saving

Innovative Design

More Intelligent

Compact Footprint

Flexible Operation

Software Program

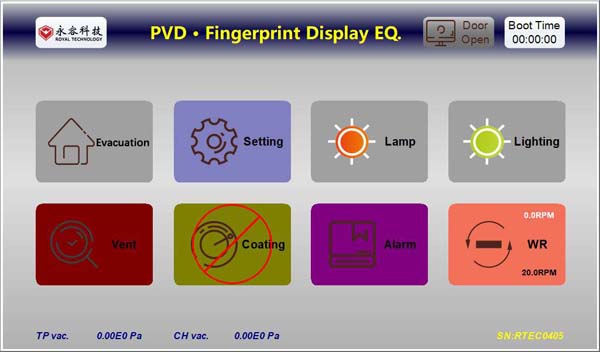

1. Higher degree of automation and more intelligent operation.

2. Icon-based HMI interface operation program for more intuitive and easy operation.

3. One-touch fully automatic and semi-automatic operation modes.

Stone Glass Aluminum Alloy

Paper Black Packaging bag Plastic card

Textile (silk) Tissue

2. Capacity: available for big workpiece, the size is up to 350*350mm

3. Flexible operation based on HMI device: processing page, curve record page, alarm page, maintenance pages etc. The data logging in and USB connection port for downloading the processing data. Auto-vacuum, auto-vent, auto-coating modules, parameters setting module etc.

4. The equipment is designed with RJ45 remote diagnosis system which is available for remote control and software upgrade in the future.

5. The required working environment is only electric power: 1Ph, 220V 50Hz, 60A;

6. Water-cooling free system, compressed air free.

7. The equipment is designed with wheels, easy move and installation on the 2nd (above the 2nd) floors.

8. It is designed with ONE set of high-precision film thickness controller, the evaporation baffle is installed to prevent coating thickness exceed the anticipated value.

9. The industrial electron microscope is designed, which can observe the whole evaporate process and take screenshots and record the videos at any time.

10) Powerful vacuum pumping system for fast cycle coating process: high turbo molecular pump, available for assembly at any direction; designed with one large volume of 2-stage rotary vane pump.

Technical performances

Ultimate Vacuum Pressure: better than 9.0*10-5 Pa;

Operating Vacuum Pressure: 6.0*10-3 Pa ~9.0*10-3 Pa;

Base Vacuum pressure: 3.0*10-4 Pa

Pumping down Time: from 1 atm to 9.0×10-3 Pa≤15 minutes ( room temperature, dry, clean and empty chamber)

Deposition source: Tungsten board filament evaporation

Operating Model: Full Automatically /Semi-Auto/ Manually

Deposition materials: Zinc, Silver, Gold, Aluminum etc.

|

Technical Configurations |

RT0405-FORENSIC |

RT0808-FORENSIC |

|

|

Vacuum Deposition Chamber |

Inner dimensions(mm): W500*D450*H500 |

Inner dimensions(mm): φ800*H800 |

|

|

Vertical orientation, front-side door opening, cubic model |

Vertical orientation, front-side door opening, cylinder model |

||

|

Material: SUS304, designed with strong and durable strengthening ribs to prevent it from deformation, |

|||

|

Drawer |

2 units, for consumable materials, tools and maintenance parts storage |

||

|

Working Auxiliary Facilities |

1Ph, AC220V, 50Hz, 6.5KW, |

3Ph, 380V,50Hz, 20KW |

|

|

Equipped with 1 set industrial water chiller |

Equipped with 1 set industrial water chiller 1 set air compressor Provided by end user: EDI water |

||

|

Footprint(L*W*H): 1300*900*1800mm |

Footprint (L*W*H): 1800*2300*2100mm |

||

|

Weight 750KGS, Ground bearing: 800kgs/sqm |

Weight 2000KGS, Ground bearing: 800kgs/sqm |

||

|

Standard Modules |

Vacuum Pumps |

Turbo molecular pump+ two-stage rotary vane pump + gate valve |

Magnetically suspension molecular pump+ |

|

Deposition |

1 set, China brand |

||

|

Online Monitoring System |

HD camera + wireless transmission module |

||

|

Evidence Holder |

1) 2D flat panel substrate holder

2) U shape panel substrate holder

|

||

|

Evaporation |

3 groups, 1KW |

3 groups, 5KW |

|

|

Vacuum Measuring |

Vacuum Gauges: 1 SET |

||