NCVM is short name of None Conductive Vacuum Metallizing, which is used for plastic parts plated which coated by vacuum deposition technology. This techniques uses each other discontinuous features, to generate a final appearance of the metallic finish and doesn’t affect the effect of the wireless communication transmission.

NCVM stands for non-conductive vacuum metallization, a type of vacuum plating technology that gives a metallic appearance to a surface while remaining electrically non-conductive performance.

NCVM is used to coat a variety of plastic materials, such as cell phones, tablet computers, and vehicle keys, without interfering with radio signals or electrostatic discharge (ESD) performance:

Benefits

NCVM coatings are resistant to abrasion, scratching, and chemicals. They also allow for inductive charging despite the coating.

Process

The NCVM process involves spraying an undercoat on a substrate, then electroplating the undercoat to form a film layer.

Applications

NCVM is used to beautify products and create a unique metal color effect. It's also used in the optical industry to create gradient color optical films for smartphones, digital cameras, and decorative parts.

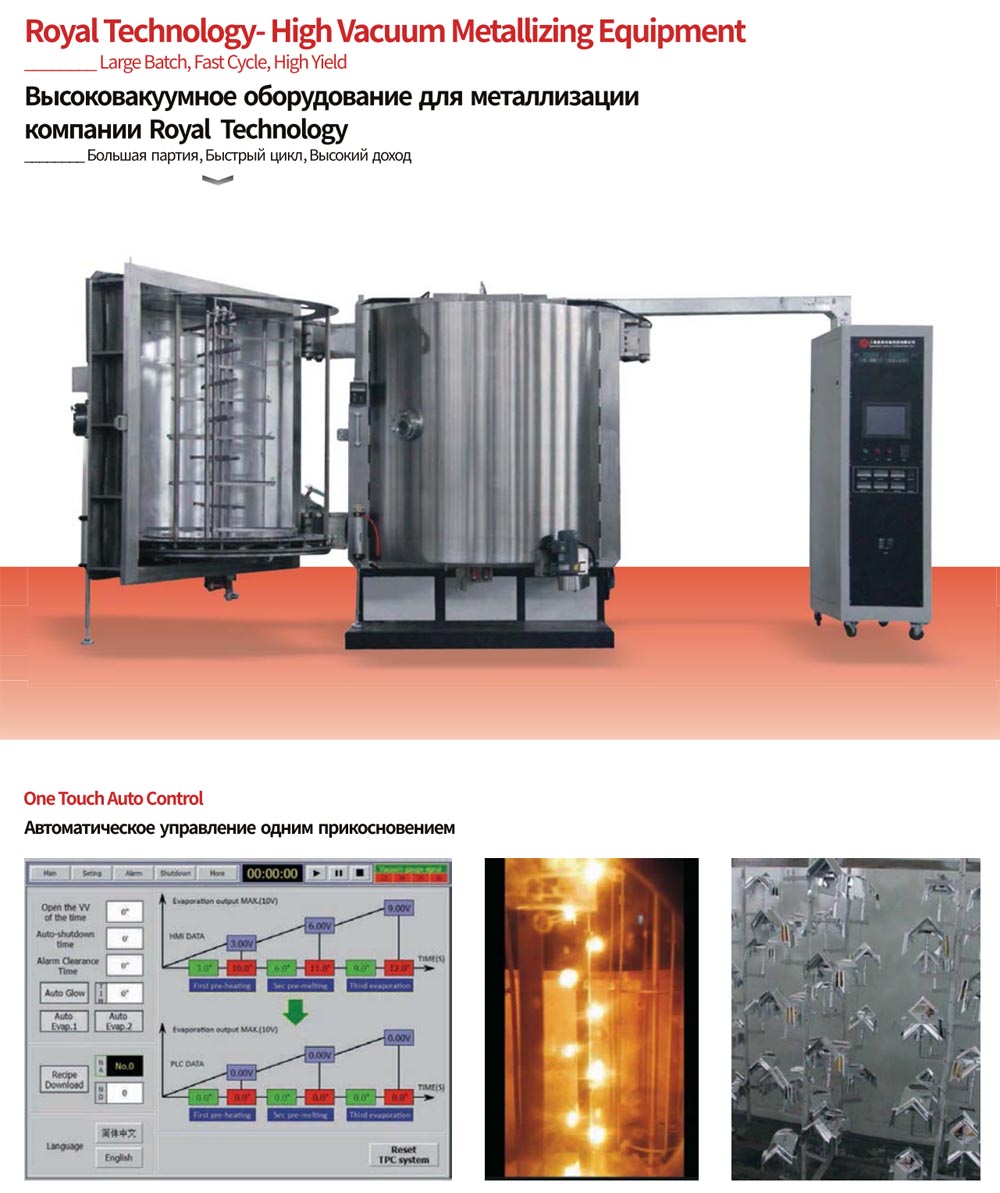

Application: NCVM Coatings On Electronic Products

Deposition Material: Indium And Sn Evaporation Coatings

Deposition Sources: Tungsten Basket, Crucible, Filament Etc.

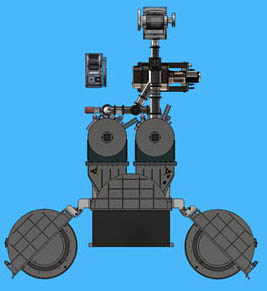

Machine Model: 2-doors, Vertical

The Substrates: plastic materials like: PC, PC+ABS, ABS, PMMA, Nylon, engineering plastics etc.

NCVM Applications: mostly for electronic product industries, communication devices. Mobile phone, telephone, smart phone, GPS satellite navigation, bluetooth headset, computer etc.

NCVM Thin Film Properties

With resistance thermal evaporation technology to evaporate high pure Indium metal and then condense on the plastic work pieces. The controlled thickness allows a non-conductive thin film on electronic parts.

- Indium material purity: over 99.99%

- Indium film thickness: around 30nm

- With high resistance value and excellent metallic finish.

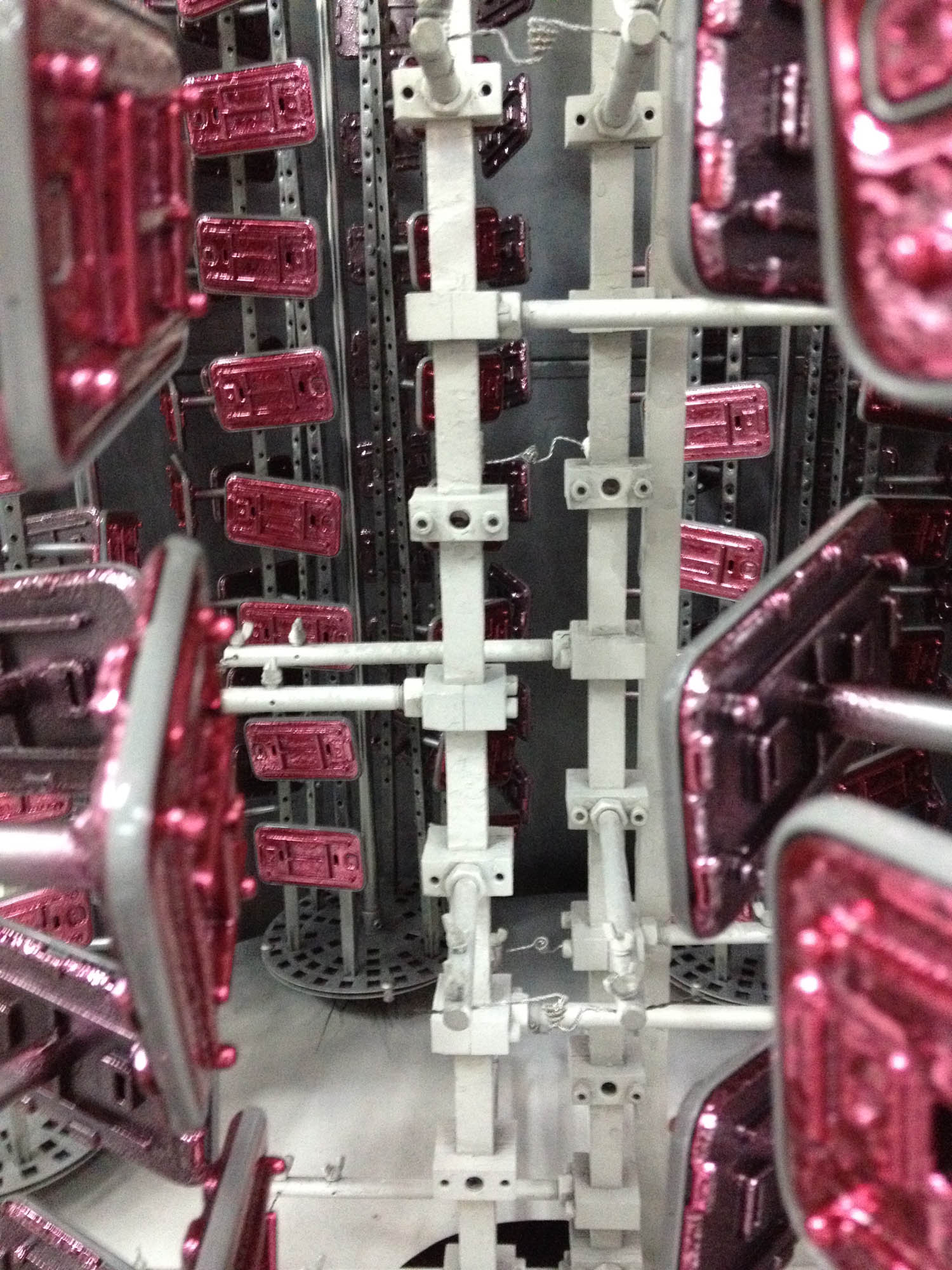

NCVM Coated Samples

2.1 The main factors affecting the effect of coatings are

- Vacuum Pressure

- Vacuum Deposition chamber size

- Evaporation materials quantity and quality

- Quality and quantity of coating materials

- Evaporation sources model selection

- Distance between product and evaporation source

- Spaces between evaporation sources

- Evaporating current working value and distribution

- Evaporation time

- Rack and planetary axis rotation speed etc.

2.2 For vertical orientation machines, the above factors can be controlled by the coating parameters pre-setting, which is an guarantee of high yield of coatings.

2.3 To improve the uniformity problem effectively, the evaporation sources (tungsten wires) are specially designed. Which are distributed in a multi-level from high to low, enable the evaporated and condensed metal vapors in a 360 degree space.

Benefits

- it is an alternative technology for electroplating products of the Chrome-Free.

- Much Lower production cost compared with traditional spraying painting method. And high qualified production rate.

- Coating process is simple and easy operation.

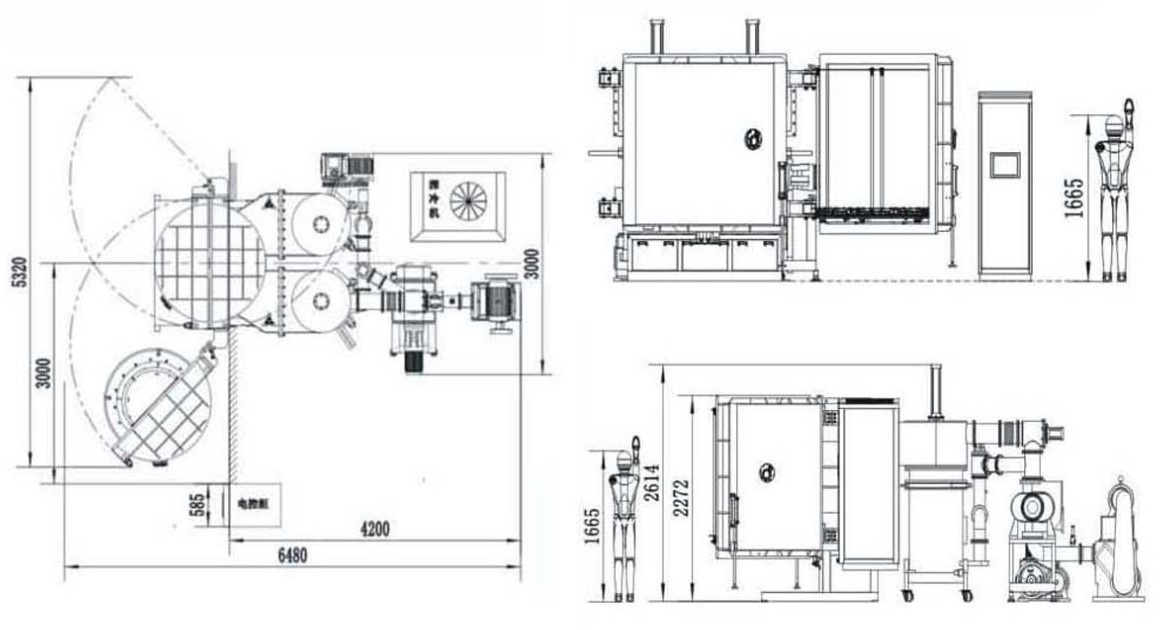

- 2-door designs can double the productivity.

- Double-group vacuum pumping system for a fast cycle: less than 12 mins.

Double- doors for higher productivity

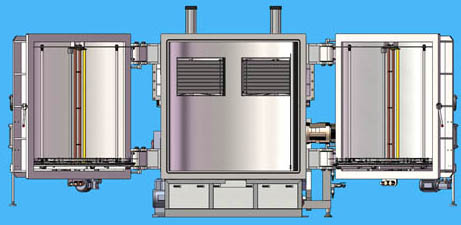

Technical Specifications

| MODEL | RT1600-NCVM |

| TECHNOLOGY | THERMAL EVAPORATION, TUNGSTEN ,FILAMENT, glow discharge |

| MATERIAL | Stainless Steel (S304) |

| CHAMBER SIZE | Φ1600*1600mm (H) |

| CHAMBER TYPE | Cylinder, vertical, 2-door |

| EVAPORTATION SYSTEM | exclusive design for NCVM coating |

| DEPOSITION MATERIAL | Tin, Indium (Sn, In) |

| DEPOSITION SOURCE | TUNGSTEN FILAMENT |

| CONTROL | PLC(Programmable Logic Controller) + Touch Screen |

| PUMP SYSTEM | Rotary Piston Vacuum Pump |

| Rotary Vane Vacuum Pump | |

| Roots Vacuum Pump | |

| Oil Diffusion pumps+ Brooks Polycold | |

| PRE-TREATMENT | UV primer coating |

| SAFETY SYSTEM | Numerous safety interlocks to protect operators and equipment |

| COOLING | Cold Water |

| POWER ELECTRICAL | 480V/3 phases/60HZ ( USA compliant) |

| 460V/3 phases/50HZ ( Asia compliant) | |

| 380V/3 phases/50HZ ( EU-CE compliant) | |

| FOOTPRINT | L9000*W4200*H3000mm |

| TOTAL WEIGHT | 10.2 T |

| AVERAGE CYCLE TIME | 15 minutes (depending on substrate material, substrate geometry and environmental conditions) |

| POWER MAX.. | 110KW |

| AVERAGE POWER CONSUMPTION (APPROX.) | 60KW |

Layout

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

Project Location: China, Vietnam, India, Thailand etc.