Royal technology has developed and built the whole supply chain for Car LOGO board PVD metalizing service. From mold design & manufacturing, thermal vacuum forming process, UV curing base/top coatings; PVD chroming metalizing till LED lighting assemble, we are able to provide a complete turn-key coating solution. If you need customized coating system, please share your thoughts and ideas with our team. Do not forget to submit your product specifications, we will work together and find the optimal solution to your needs.

The RTEP2200 metalizing system was custom designed and manufactured for Car LOGO board chrome coating. With the PVD thermal evaporation technology, which deposits thin high reflection film on PMMA (Acrylic) surface, gives outstanding coating layers as shown below: during day time, sign symbols have a solid metal look ( stainless steel effect ); while at night, they are illuminated ( LED light inside is installed ) from front, back and side views.

Car Logo Aluminum Vacuum Metalizing Machine Models

Model

Chamber size

(MM, inner)

Evaporation Power(kVA)

Working Power Environment

Chamber Type

RTEP3600

φ3600xH1700

80

3Ph, AC380V,50HZ

Cylinder

RTEP2200

φ2200xH1500

50

Cylinder

RTEP2500-HMDSO

φ2500xH2500

50

Cylinder

RTEP6600

L6600xH3800

100

Cube

RTEP4500

L4500xH3200

80

Cube

3Ph, 220 to 440V,60HZ

With PVD resistant thermal evaporation technology, this process produces a coating that simulates the appearance of electroplated silver, gold, bronze and other brilliant or matte electroplated finishes.

Royal Technology has designed, built and installed over 100 sets of thermal evaporation coating systems worldwide, encompassing a variety of applications and industries, such as:

Automotive plastic exterior/interior trims

Vehicle lighting and components

Commercial, industrial and residential LED lighting reflectors

Cosmetic packages

Glassware and mirrors

Electronic consumer products

EMI shielding and NCVM films

Toy parts and sporting goods

Home appliances of washing machines and various accessories of furniture

Fashion, clocks and watches

Only to name a few, in many other areas PVD vacuum metallizing processes are continue to be used and developed in the coating industry.

The PVD metallizing process gives the objects a high shiny, reflective, metallic look which can be in different colors.

Type:

Vertical orientation, Cylinder, 1-door, front opening.

Design Features:

Robust structure design and high quality configurations

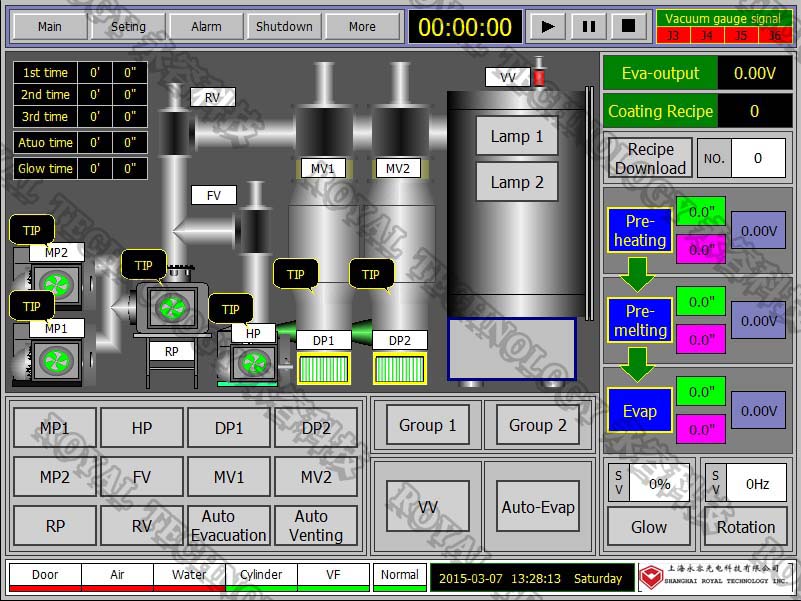

PLC + Touch Screen Operation System, fully automatic / manual control

Fast Vacuum Evacuation System

Exclusively designed rotating Carousel structure for easy loading/uploading

Easy access to the working environment for maintenance

Technical Specifications:

Performance

1. Ultimate Vacuum Pressure: better than 5.0×10-6 Torr.

2. Operating Vacuum Pressure: 1.0×10-4 Torr.

3. Pumping down Time: from 1 atm to 1.0×10-4 Torr≤3 minutes ( room temperature, dry, clean and empty chamber)

4. Metalizing material ( evaporation): Al, Cr, Sn, Ti, SS, Cu… etc.

5. Operating Model: Full Automatically /Semi-Auto/ Manually

Structure

The vacuum coating machine contains key completed system listed below:

1. Vacuum Chamber

1.1 Size: Inner Diameter 2200mm

Inner Height: 1500mm

1.2 Material: Vacuum Chamber SUS304

Door and flanges SUS304

Chamber strengthen structure: SS41 mild steel, with painted finishing surface treatment

Chamber chassis SS41 mild steel with painted finishing surface treatment

1.3 Evaporation Shield : SUS304

1.4 View Window: on chamber door

1.5 Vacuum Chamber Venting Valve (including silencer)

1.6 Door: SUS304 material

2. Rouhging Vacuum Pumping System (Backing Pump Package)- Leybold

3. High Vacuum Pumping System (Diffusion Pump + Cold trap device)- Leybold

4. Electrical Control and Operation System- PLC+ Touch Screen

4.1 Main circuit: None-fuse breaker switch, electromagnetic switch, C/T in series type

4.2 Evaporation Power

4.3 Evaporation Control System

4.4 Operation System: Touch Screen + PLC, recipe control and data logging, Auto shutdown, auto evacuation, auto coating

4.5 Vacuum Pressure Measuring System

Vacuum Gauge: Pirani + Penning gauge

Thermocouple Gauge: 760 Torr ~ 5*10-4 Torr

4.6 Alarm System: Compressed air pressure , Cooling water flow, Mis-operation

4.7 Power Load Indicator: Voltage indicator and load current indicator

5. Deposition System

5.1 Tungsten filament evaporation source

5.2 Cr/Al wires

6. Sub-System

6.1 Air Compressed Valve Control System

6.2 Cooling Water System:Water flow pipe and switch valve system

6.3 Polycold (-120~-145℃) Brooks Cryopump for option.

7. Working Environment

Compressed Air: 5~8kg/cm2

Cooling Water: Water-In Temperature: 20~25℃, 200 Liter/min,

Water-In Pressure: 2~3 kg/cm2,

Power: 3 Phase 380V 50Hz(60Hz), 100kVA

Installation Area: (L*W*H) 9000*4200*3000mm

Exhaust: Vent for mechanical pumps

Built: 2015

Location: South Korea

Applications: Automobile LOGO board, PC/PMMA Chrome Coating, Aluminum/Silver/Copper/ SS wires Metalizing.