A PVD (Physical Vapor Deposition) arc decorative coating machine is a type of equipment used in the process of applying thin films or coatings onto various surfaces for decorative or functional purposes. PVD coating machines use a process where solid metal or ceramic material is vaporized in a vacuum environment and then deposited onto the target surface as a thin film. The "arc" in the name refers to the method of vaporizing the material, which typically involves using an electric arc to heat and evaporate the source material. These machines are commonly used in industries such as automotive, aerospace, electronics, and decorative coatings to apply coatings that provide properties such as wear resistance, corrosion resistance, improved hardness, and aesthetic appeal.

The decorative coatings applied by PVD arc machines can come in various colors and finishes, making them popular for applications where both functionality and appearance are important, such as in jewelry, watches, eyewear, and architectural hardware.

Why PVD arc decorative coatings?

PVD arc coating offers several advantages over other coating methods, making it a popular choice for various applications. Some of the key advantages of PVD arc coating include:

High Quality Coatings: PVD arc coating produces high-quality, dense coatings with excellent adhesion to the substrate material. This results in coatings that are durable, wear-resistant, and provide good protection against corrosion.

Uniformity: PVD arc coating provides uniform thickness across the entire surface being coated, ensuring consistent performance and appearance.

Wide Range of Materials: PVD arc coating can be used to deposit a wide range of materials, including metals, ceramics, and even some plastics. This versatility allows for the creation of coatings with specific properties tailored to the application requirements.

Environmentally Friendly: PVD arc coating is a clean and environmentally friendly process since it is performed in a vacuum environment without the use of hazardous chemicals. This makes it a preferred choice for industries focusing on sustainability.

Controlled Deposition: The PVD process allows for precise control over the deposition parameters such as temperature, pressure, and deposition rate, resulting in coatings with specific properties and characteristics.

No Thermal Stress: PVD arc coating is a low-temperature process, which minimizes thermal stress on the substrate material. This makes it suitable for coating temperature-sensitive materials such as plastics and certain alloys.

Aesthetic Appeal: PVD arc coatings can be produced in a wide range of colors and finishes, making them popular for decorative applications where aesthetic appeal is important.

Improved Adhesion: The high-energy arc process in PVD coating promotes good adhesion between the coating and the substrate material, ensuring long-term performance.

Maintenance and Cost Savings: PVD coatings are known for their durability and longevity, reducing the need for frequent recoating or maintenance, which can result in cost savings over time.

Overall, the advantages of PVD arc coating make it a preferred choice for industries looking for high-quality, durable, and customizable coatings for a variety of applications.

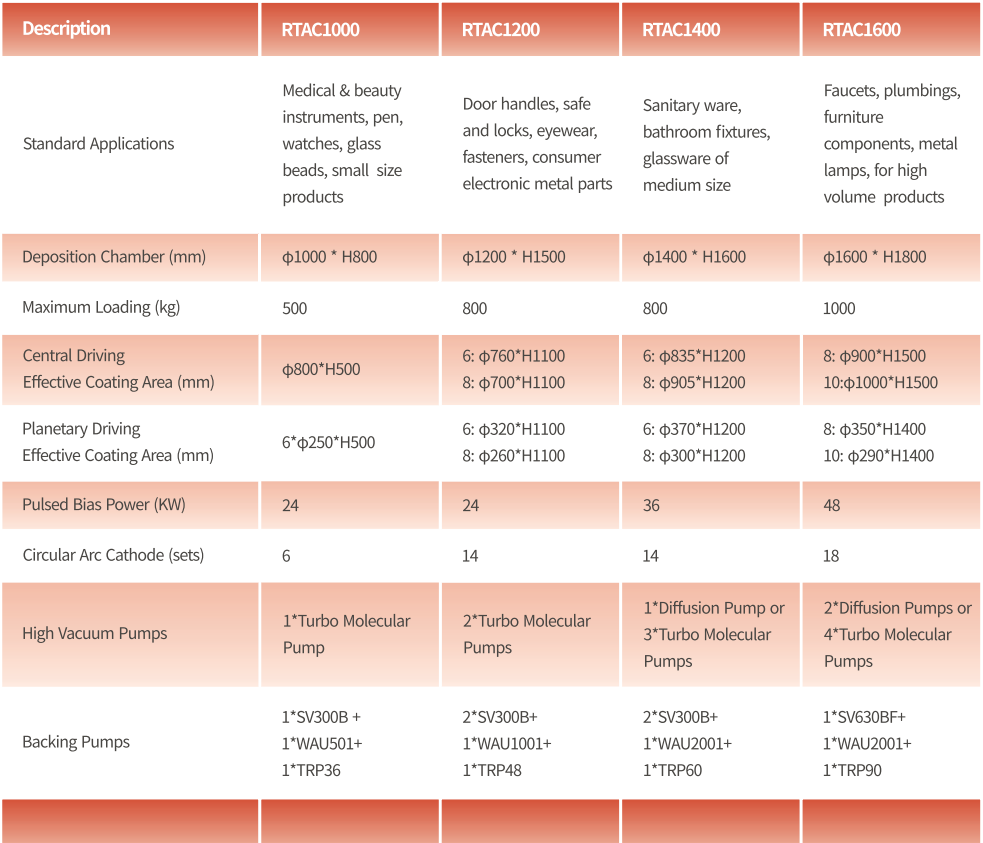

Royal technology has developed Small, Medium, Big and Large sizes standard decorative arc plating machines for various parts.

RTAC1000, RTAC1200, RTAC1400, RTAC1600 models. These models have been widely applied with applications of:

- Bathroom and shower fixtures

- Sanitary ware and plumbing applies

- Door handles, fasteners, safe and locks

- Glass and ceramic products

- Eyewear

- Writing Instruments

Only to name a few, but for more applications, please contact Royal Technology .

RTAC1000 machine – small size for small items like: watch parts, medical instruments, pens…

RTAC1200 machine – medium size for door handles and security locks, metal fasteners, consumer electronics.

RTAC1400- medium size arc plating machine for sanitary ware, bathroom fittings, glassware, ceramic ware.

RTAC1600- medium size arc plating machine for faucets, brass tap ware, plumbings, furniture, metal wire lamps.

Advantages

- Many bright colors of final finishing

- Excellent scratch resistance

- Enables longer life of products

- Environmentally-friendly process

- Robust and high volume design machine

- HMI friendly operation system

- Low maintenance

- Low cost of ownership

ASTER, MORE STABLE, BRILLIANT FINISHING

- Cathodic arc is an upgraded design to optimize emission of droplets

- The Ion evaporator with an auto pneumatic driving ignition system, manual ignition button to control the target and efficiently improve the utilization

- IGBT model of cathodic arc inverter power supply, arc discharge from 30A to 200A, arc current can be set and adjusted by PLC on the touch screen

- Cathodic arc with direct cooling method, low temperature evaporation is available.

- Stable process operation in a wide pressure range.

FLEXIBLE GAS DISTRIBUTION SYSTEM

- 4 channel gas mass flow control system

- 3-1 or 2-2 channel gas mixing to meet flexible coating processing demands, distributed on modular designed board

- With needle valve, pressure regulator and high precision trimming valve to control the gas introduction, can be switched either manually or automatically

STANDARD, MODULAR DESIGN

- PS electrical enclosure, designed and manufactured strictly following CE standards

- Central control cabinet with PLC, power output control and general power distributor

- Operating software program in PLC is exclusive developed by Royal Technology, each set machine is ready for system upgrading

CE Standard Electrical Cabinet

General Information

RTAC1000 Design Advantages

- Small Footprint

- Fast Cycle Times

- Low Production Cost

- Maximum 6 arc cathodes for fast deposition of coatings

- Suitable for all small work pieces

- Optional DC/MF sputtering cathodes

RTAC1200 Design Features

- Compact footprint design

- Robust machine for most decorative coating parts

- Efficient pump-down,up to 3 turbo molecular pumps

- Easy maintenance and extremely low power consumption

- Maximum 14 arc cathodes for fast deposition of coatings

- Pulsed Bias power for arc discharging

- Optional Ion Source Unit

RTAC1400 Design Features

- Robust equipment

-

Efficient pump-down, up to 3 turbo molecular pumps or

1-diffusion oil pump - Maximum 14 arc cathodes for fast deposition of coatings

- High volume of medium substrates loading

- Pulsed Bias power for arc discharging

- Reduced cycle decorative coatings

RTAC1600 Design Features

- Robust equipment.

- Efficient pump-down,up to 4 turbo molecular pumps or 2 diffusion oil pump.

- Maximum 18 arc cathodes for fast deposition of coatings.

- High volume of big substrates loading.

- Pulsed Bias power for arc discharging.

- Optional DC/MF sputtering deposition sources.

Machine Model: RTAC1200

Project Location: Iran

Project Time: 2017