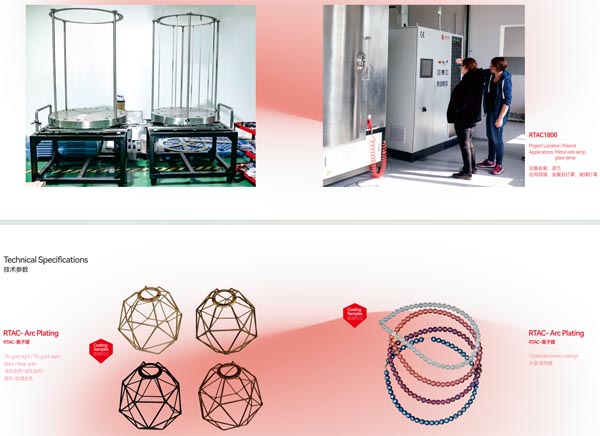

Glass Lamp and Metal Wire Lamp PVD Coating Machine PVD coatings on glass lamps can offer various decorative finishes, including metallic, colored, or even transparent coatings that can alter the light transmission properties of the glass. These coatings can help create custom designs, improve the lamp's aesthetic appeal, and provide protection against wear and tear. RTAC1800 is designed and fabricated for glass lamps and metal wire lamps PVD decorative coatings. Gradually, this model is used for bigger size items like kitchen stainless steel washing basins, ceramic basins etc.

PVD decorative coatings can also be applied to glass lamps to enhance their aesthetics, durability, and functionality. Coating glass lamps with PVD can offer a range of benefits, including improved scratch resistance, increased light reflection, and a variety of decorative finishes.

When PVD coatings are applied to glass lamps, the process typically involves the following steps:

Cleaning: The glass surface of the lamp is cleaned thoroughly to ensure the coating adheres properly.

Preparation: Any necessary masking or protection of areas not to be coated is applied.

Vacuum Chamber: The glass lamps are placed in a vacuum chamber along with the metal or other material that will be used for the coating.

Evaporation: The material for the coating is evaporated in the vacuum chamber, forming a vapor.

Deposition: The vaporized material condenses onto the surface of the glass lamp, creating a thin, uniform coating.

Finishing: After the coating process, additional finishing steps may be taken to enhance the appearance and durability of the coated glass lamps.

PVD coatings on glass lamps can offer various decorative finishes, including metallic, colored, or even transparent coatings that can alter the light transmission properties of the glass. These coatings can help create custom designs, improve the lamp's aesthetic appeal, and provide protection against wear and tear.

The use of PVD coatings on glass lamps is popular in the lighting industry for creating high-quality, visually appealing products. If you have any specific questions or need more information about PVD decorative coatings on glass lamps, feel free to ask!

PVD coated lamps

Capacity:

| Code | Dimensions(mm) | Rack Model | Planetary Rods (Qty.) | Loading layers | Loading Qty. |

| 1 | φ250*H227±2mm | Rack 1 | 12 *φ300 | 6 | 72 |

| 2 | φ300*H260±2mm | Rack 1 | 12 *φ300 | 5 | 60 |

| 3 | φ200*H180±2mm | Rack 2 | 18*φ200 | 6 | 108 |

| 4 | φ180*H163±2mm | Rack 2 | 18*φ200 | 7 | 126 |

| 5 | φ140*H125±2mm | Rack 3 | 24* φ140 | 8 | 192 |

Metal Wire Lamps Capacity: 40~80 pieces, depends on lamp size and uploading method.

Highlights

-

Installation online instruction

-

Machine Operation & Coating process training: online remote.

-

Ready for power/water/gas connection

-

Plug-in integrated design

-

Industrial PC + Siemens PLC + SCADA ( Supervisory Control And Data) upgrade software program

General Information

- The multi arc vacuum coating system mainly for decorative coatings.

- Benefits: eco-environment, easy to operate, compact foot print, low cost of owner ship, fast substrate exchange.

-

Coating Colors: gold, black, brown, grey, Chrome colors etc.

Gold Colors: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Colors: TiCN, TiAlN, TiCN+Au-Cu, TiAlN+Au, Cu

Chrome colors: CrN, Ti, Cr

Gray Colors: stainless steel, stainless steel (N)

Brown Colors TiCN, TiAlCN, ZrC

Blue Color: TiO, CrO, TiALN

Black Colors: TiC, TiC+iC, TiCN, TiAlN, TiAlCN - Substrates: stainless sheets and tubes, metal alloys, glass, ceramic materials

- Coatings Advantages: high shiny and bright colors, strong adhesion & excellent scratch protection, fast deposition rate, good diffraction.

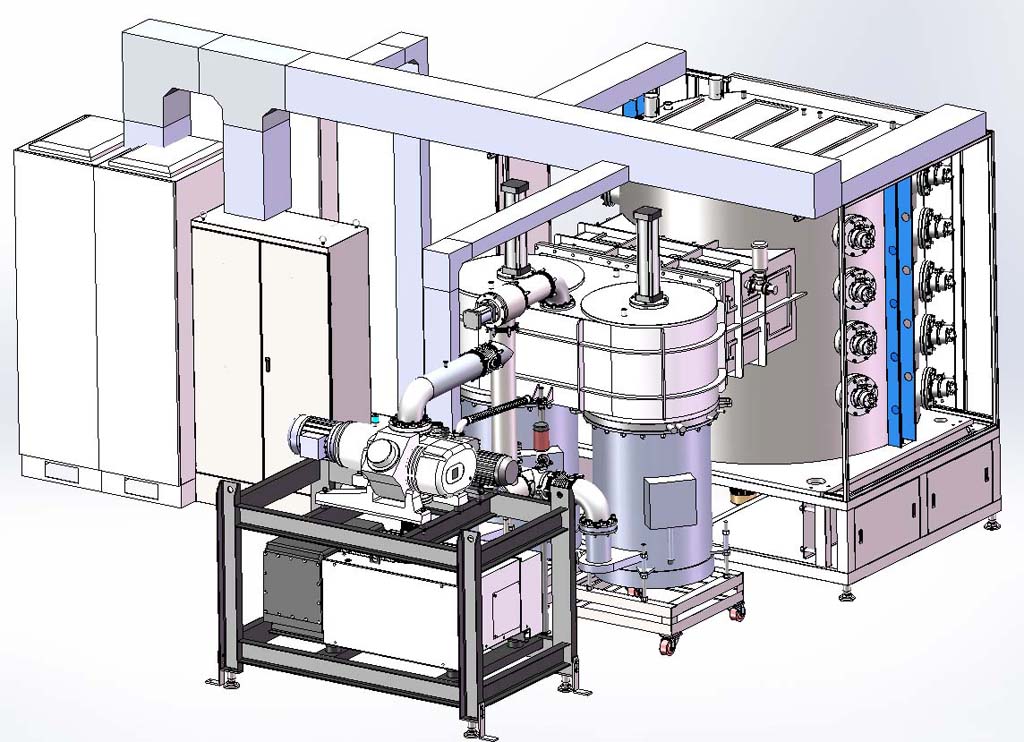

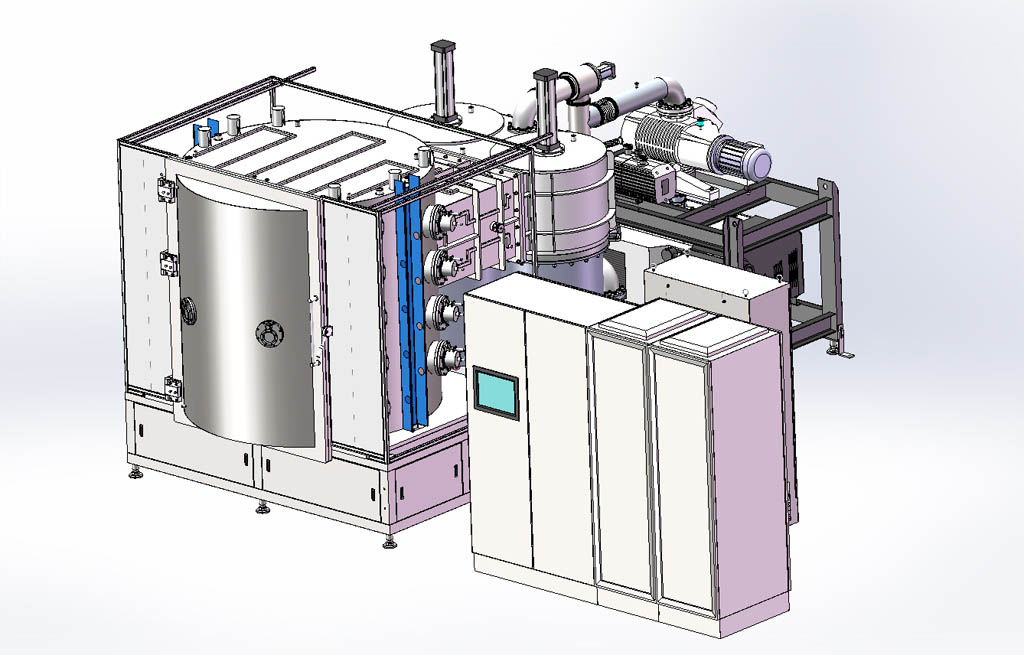

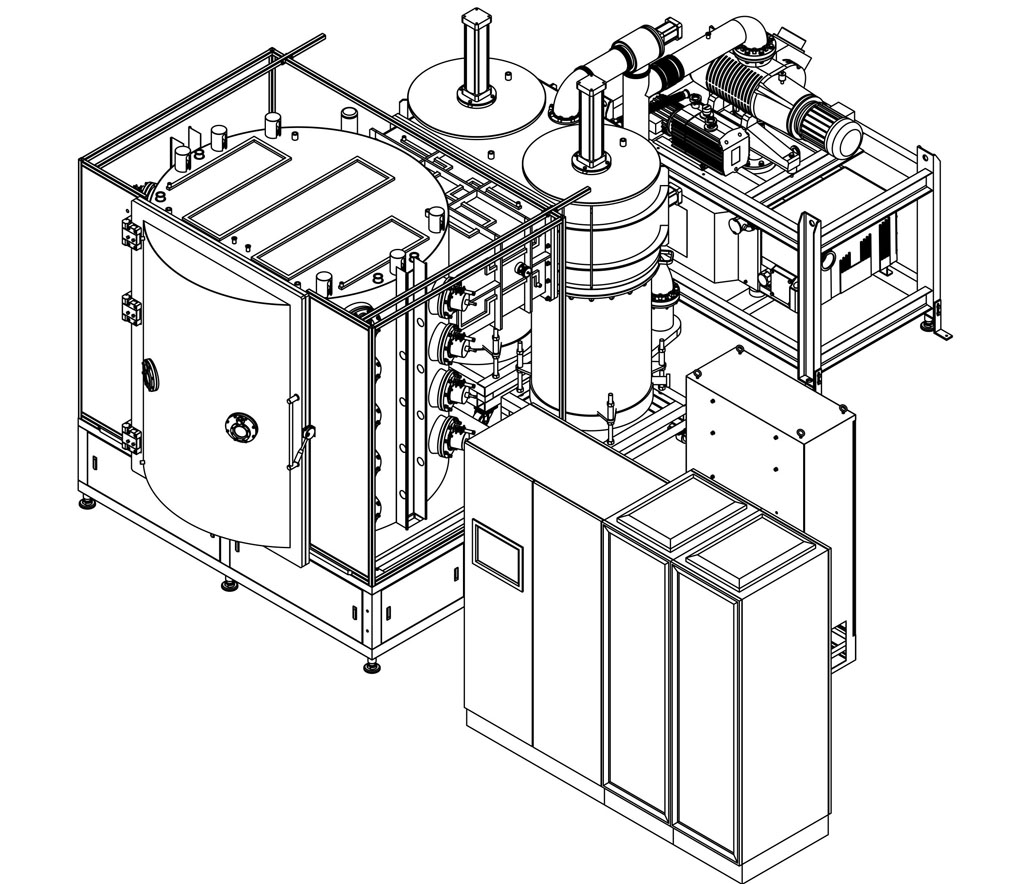

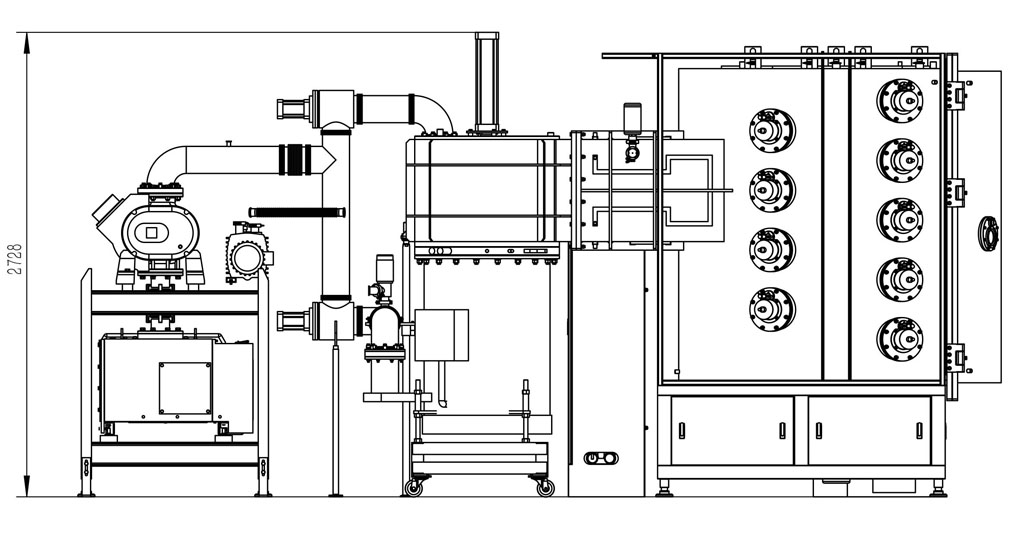

Features

This series equipment consists of: vacuum chamber, vacuum pumps, arc sources,

spindle & jack, jigs structure, heating & cooling, water & gas (distribution), electrical control & operation systems etc. High lights of the design futures:

1. Flexibility: Arcs are standardized for flexible and quick exchange;

2. Versatility: can deposit variety of base metals and alloys; optical coatings, hard coatings, soft coatings, compound films and solid lubricating films on the metallic and non-metallic materials substrates. 3. Powerful pump set for short cycle time and high productivity.

4. Multiple deposition sources for different substrates materials.

5. Royal exclusive arc sources to guaranty high coatings quality, none color difference.

6. Turnkey coating solutions.

Performance

1 .Ultimate Vacuum Pressure: better than 8.0×10-4 Pa

2. Operating Vacuum Pressure: 1.0×10-2 Pa.

3 .Pumping down Time: from 1 atm to 8.0×10-3Pa≤15minutes ( @room temperature, clean and unloading)

4. Leaking Rate: 9.0-5 Pa m3/ sec. Or better than 0.67Pa in 1 hour after shut down the machine from ultimate pressure.

5. Deposition Materials: Stainless steel, Cr, Ti, TiAl, Zr … etc.

6. Deposition Sources: Arc cathodes

7. Operating Model: Full Automatically /Semi-Auto/ Manually

8. .Safety Circuitry and Interlocks: numerous safety interlocks to protect operators and equipment ( water, current etc.) I: Heating: up to 250℃,

Layout

| Description | RTAC1800 |

| Standard Applications | Metal wire lamps, glass lamps, kitchen SS basins |

|

Deposition Chamber

(mm) |

φ1800 * H1800 |

|

Maximum Loading

(kg) |

1000 |

| Planetary Driving Effective Coating Area |

10*φ330mm or 12*φ300mm or 18*φ200mm or 24*φ140mm for options Effective height: 1400mm |

|

Pulsed Bias Power

(KW) |

48 |

| Circular Arc Cathode (sets) | 18 |

| High Vacuum Pumps |

2* Diffusion Pumps or

4* Turbo Molecular Pumps |

| Backing Pumps | 1*SV630BF+1*WAU2001+1*TRP90 |

| Operation & Control | IPC + Siemens PLC + SCADA software |

| Max. Power Consumption (Approx.) | 170KW |

| Average Power Consumption(Approx.) | 80KW |