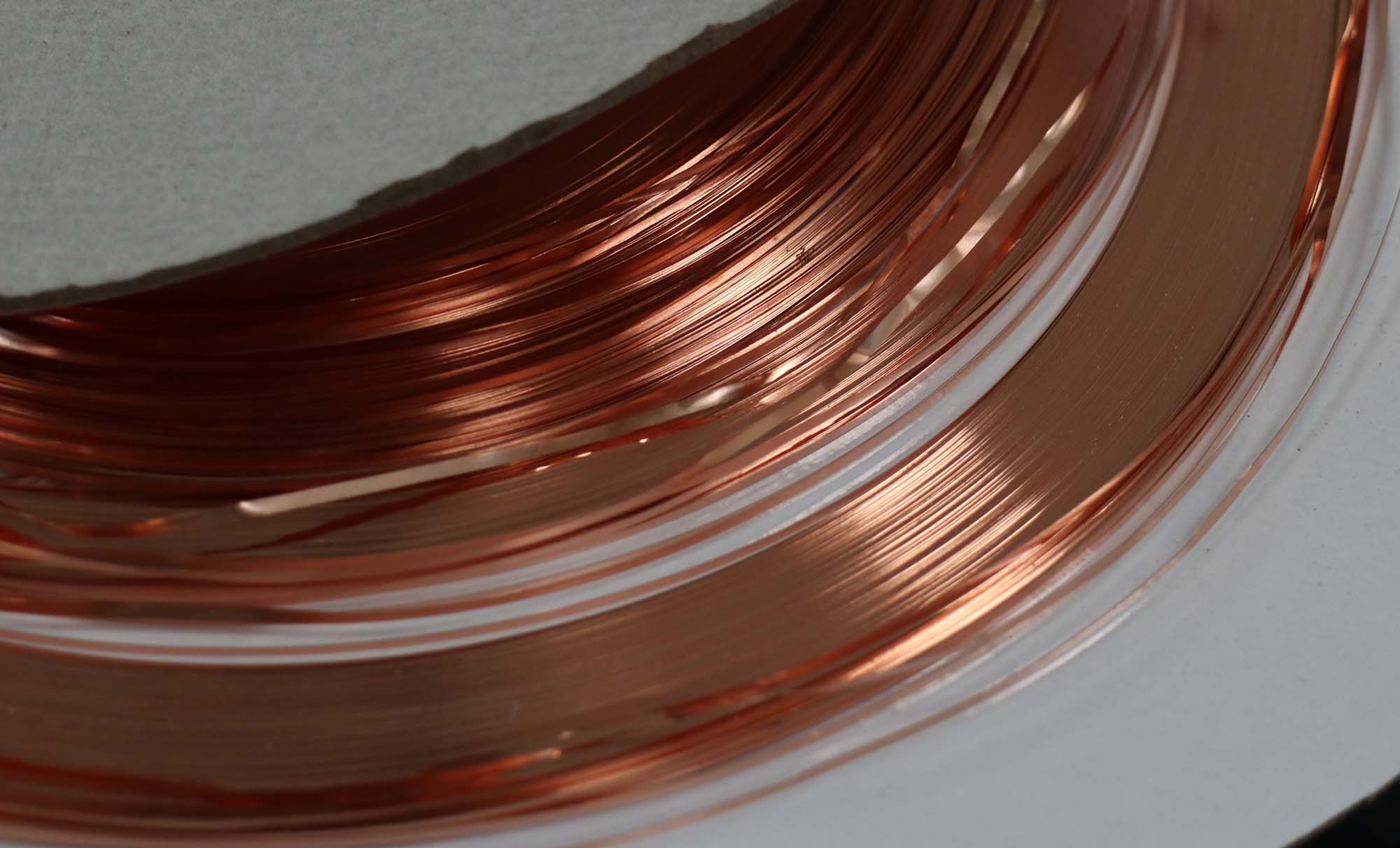

Key Types of the existing vacuum coating production line for wires and strips substrates

(1) Separated type

The coating line doesn’t contains substrates ( wires and strips)’s pre-cleaning device. It puts the steep strip roll which has been cleaned before into a closed vacuum container which equipped with unwinding, pre-heating, coating and rewinding devices. After the vacuum evacuation to desired working vacuum pressure, starts the pre-heating process, and then metal films deposition. This type of equipment’s structure is simple, but very low production efficiency and the coated substrates has issue of the second-time contamination.

(2) Air- to- Air full continuous coating type

The Air-to Air full continuous coating line is a completed continuous coating process processes which including cleaning pre-treatment in the atmosphere environment, and then the substrates ( strips or wires) enters into the vacuum chamber to get metal films deposited, in then end it back to atmosphere environment again through buffering chambers.

The air to air continuous coating line key structural modules:

A: Substrates (strips or wires) cleaning pre-treatment module

B: Cooling down module

C: Annealing module

D: Film deposition chamber

E: Loop devices and vacuum buffering chamber.

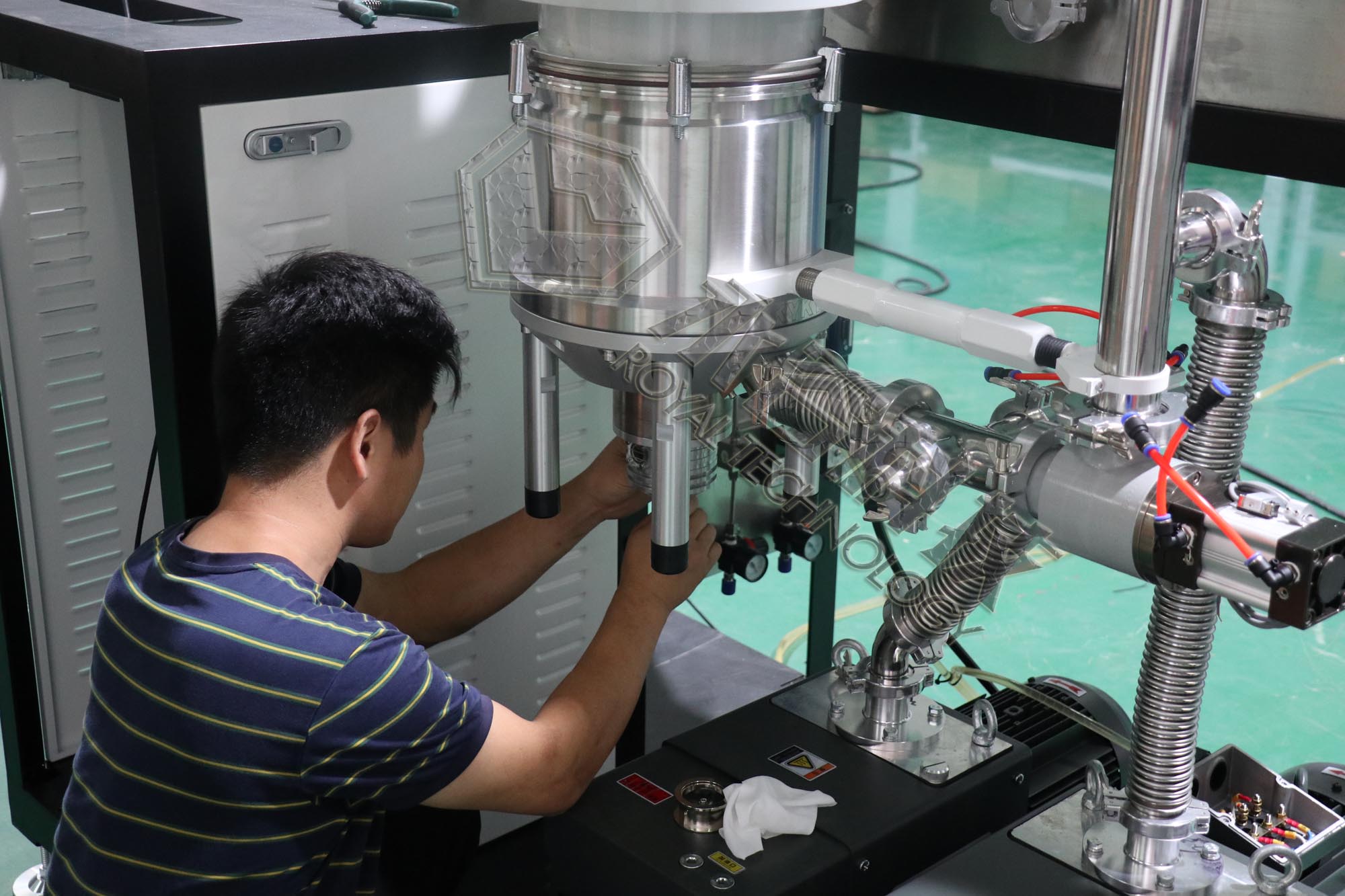

The whole coating line’s structure, operation and control system is more complex, extremely high investment but the advantages of high output and sharping down production cost efficiently make it is very attractive for manufacturers. Royal technology’s team has built the industrial production line in 2019 based on a small demo device, we are excited to announce that outsourcing coating service to us is available now.

Welcome to consult us who is interested in the continuous coating line’s invest, we provide the turnkey coating solution.

(3) Universal Type

Universal type is a coating line which combined substrates ( strips) cleaning pre-treatment, hot dip plating and vacuum coating 3 processes to form a complete continuous production line. Which makes the went and dry coating processes are compatible with each other and also can produce high quality and economical metal coated strips

(4) Multiple-layers coating type

The production line combine several different PVD coating methods: Electron beam evaporation coating, magnetron sputtering deposition and plasma enhanced CVD deposition.

With E-beam pre-heating, glow discharging plasma bombardment cleaning surface treatments on the strips, then deposit multi-layers on the surface with different deposition processes.

The first layer requires strong adhesion between metal film and substrate surface, so magnetron sputtering deposition is used; the second layer takes Electron-beam evaporation method to deposit various coating materials, it has high electron beam energy density and high heating temperature performances; the third layer uses plasma enhanced CVD deposition method to generate a high uniformity, fine finishing, high hardness and stable chemical characters film, it is good choice for the protective layer.

Come to an inclusion, the strips multiple-layer coating type is still in primary stage of R&D, also its high production cost and low productivity disadvantages makes manufactures select the hot dipping and electroplating conventional methods. However, its high extra added value on products and environmentally friendly features show it is a good prospective application.

Royal Technology provides both coating service and inline sputtering system. Please contact us if you are interested in this application.

Share us your ideas, we assit you to become true.