Physical vapor deposition (PVD) is a process used to create a thin but durable metal coating on various surfaces, including sanitary ware like faucets,hand and head showers, and bathroom fixtures. PVD coatings provide a range of benefits such as improved hardness, scratch resistance, and aesthetic appeal.

These coatings are created in a vacuum environment where metal atoms are evaporated and then condensed onto the surface of the object being coated. This process results in a thin film of metal that adheres well to the substrate and can be used to create a variety of finishes, including chrome, gold, bronze, and black.

Faucets as important consumption of our daily life, consumers and manufactures are more focusing on the creative design & surface treatment process. PVD finish is more welcomed due to its low production cost, environmentally friendly, extremely durable, highly brilliant, and guaranteed for life against tarnishing advantages.

PVD is short name for Physical Vapor Deposition. This process creates a ionized thin films to the faucet resulting in the most durable finish available today. Products with PVD finish will not corrode, discolor, or tarnish.

Faucets with PVD finished last longer life time, can pass the Neutral salt spray test over 200 hours.

The PVD process typically involves the following steps:

Cleaning: The surface of the sanitary ware is thoroughly cleaned and prepared to ensure good adhesion of the PVD coating.

Vacuum Chamber: The sanitary ware is placed in a vacuum chamber along with the metal that will be used for the coating.

Evaporation: The metal is heated in the vacuum chamber, causing it to evaporate and form a vapor.

Deposition: The metal vapor condenses onto the surface of the sanitary ware, forming a thin and uniform coating.

Finishing: After the coating process is complete, the sanitary ware may undergo further finishing processes to enhance its appearance and durability.

PVD coatings on sanitary ware are known for their durability, resistance to corrosion, and ability to maintain their finish over time. They are commonly used in high-end bathroom fixtures to provide a luxurious and long-lasting appearance.

If you need more specific information or have any questions regarding PVD decorative coatings on sanitary ware, feel free to ask!

Brass faucets, brass taps, handles

Bathroom fittings like: zamak plates, plumbings, shower heads

Stainless steel pipe faucets,

ABS and PPS decorative components

PVD finish properties

Exceptional aesthetic finish

Uniform coating thickness and colors

Superior resistance to wear and corrosion

PVD coating has a high level of hardness

PVD coating is not discolor or tarnish with a proper daily take care

PVD finishes available

Brushed PVD colors

Mirror PVD colors

Matte PVD colors

Gold, rose gold, brass, charcoal gray, graphite black, bronze, blue, white Chrome, black nickle, stainless steel finishes, blue etc.

Royal technology provides you not only the coating system but the total coating solutions, we offer you turnkey-service.

Royal technology provides you not only the coating system but the total coating solutions, we offer you turnkey-service.

From LPDC (low pressure die casting); peeling, cutting, CNC machining, robot grinding, automatically polishing line; till electroplating, ultrasonic cleaning, drying, PVD plating plants… the whole factory’s design plan and machines.

Each process’s operation you demand, we have experts to guide you.

Advantages

Royal Technology’s newest generation of PVD coating system with Remote Control and diagnosis functions: Industrial PC and Siemens PLC are equipped for more stable, more Powerful SCADA data processing capability.

- High ionization rate, high through put,

- Large capacity to satisfy mass production,

- IPC remote control and operation guidance

- Coating Process – online remote training by our own software program.

- Plug-in designed and fabricated coating system, installation can be accomplished with online instruction.

General Information

- The multi arc vacuum coating system mainly for decorative coatings.

- Benefits: eco-environment, easy to operate, compact foot print, low cost of owner ship, fast substrate exchange.

-

Coating Colors: gold, black, brown, grey, Chrome colors etc.

Gold Colors: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Colors: TiCN, TiAlN, TiCN+Au-Cu, TiAlN+Au, Cu

Chrome colors: CrN, Ti, Cr

Gray Colors: stainless steel, stainless steel (N)

Brown Colors TiCN, TiAlCN, ZrC

Blue Color: TiO, CrO, TiALN

Black Colors: TiC, TiC+iC, TiCN, TiAlN, TiAlCN - Substrates: stainless sheets and tubes, metal alloys, glass, ceramic materials

- Coatings Advantages: high shiny and bright colors, strong adhesion & excellent scratch protection, fast deposition rate, good diffraction.

Features

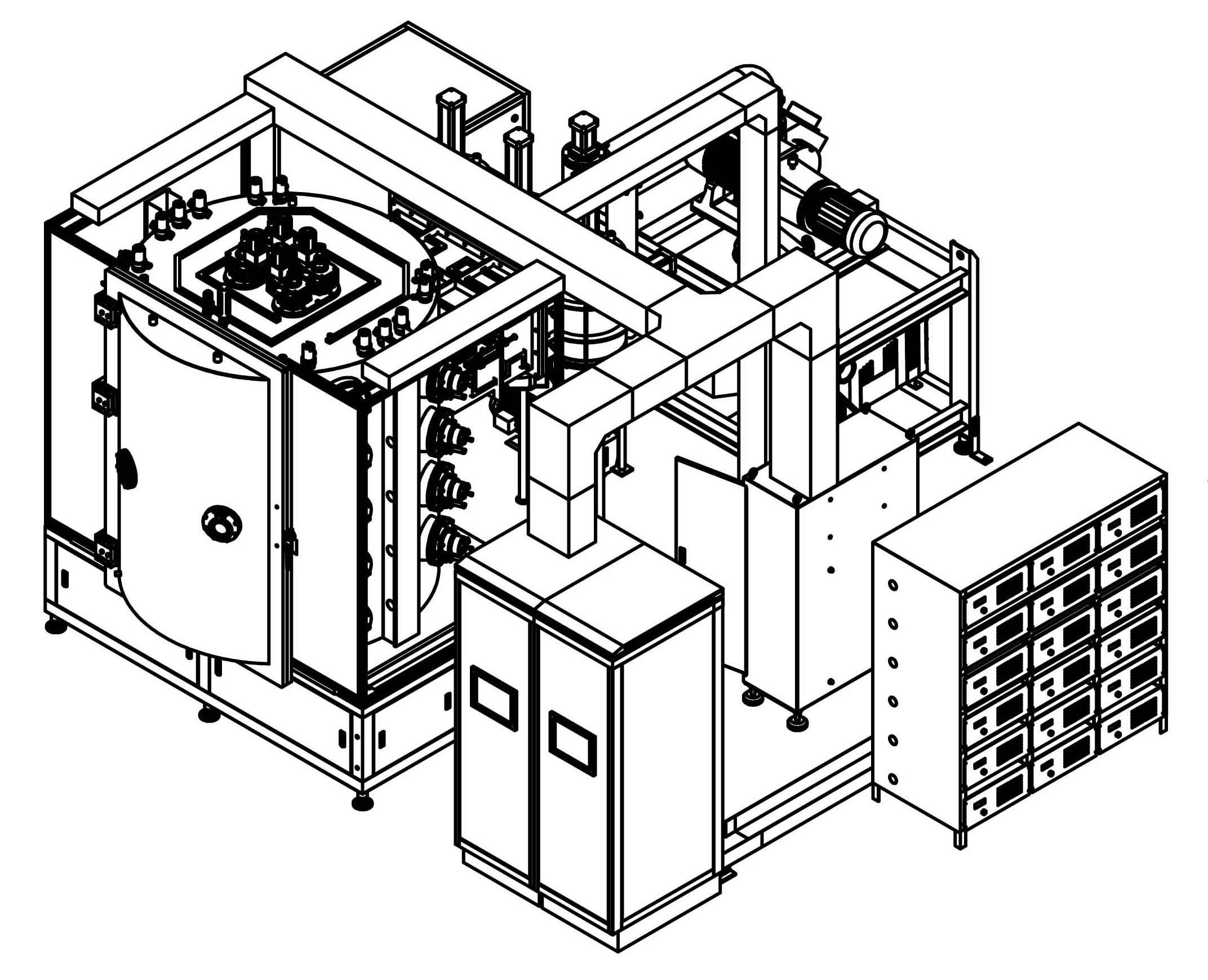

This series equipment consists of: vacuum chamber, vacuum pumps, arc sources,

spindle & jack, jigs structure, heating & cooling, water & gas (distribution), electrical control & operation systems etc. High lights of the design futures:

1. Flexibility: Arcs are standardized for flexible and quick exchange;

2. Versatility: can deposit variety of base metals and alloys; optical coatings, hard coatings, soft coatings, compound films and solid lubricating films on the metallic and non-metallic materials substrates. 3. Powerful pump set for short cycle time and high productivity.

4. Multiple deposition sources for different substrates materials.

5. Royal exclusive arc sources to guaranty high coatings quality, none color difference.

6. Turnkey coating solutions.

Performance

1 .Ultimate Vacuum Pressure: better than 8.0×10-4 Pa

2. Operating Vacuum Pressure: 1.0×10-2 Pa.

3 .Pumping down Time: from atm to 8.0×10-3Pa≤15minutes ( @room temperature, clean and unloading)

4. Leaking Rate: 9.0-5 Pa m3/ sec. Or better than 0.67Pa in 1 hour after shut down the machine from ultimate pressure.

5. Deposition Materials: Stainless steel, Cr, Ti, TiAl, Zr … etc.

6. Deposition Sources: Arc cathodes

7. Operating Model: Full Automatically /Semi-Auto/ Manually

8. .Safety Circuitry and Interlocks: numerous safety interlocks to protect operators and equipment ( water, current etc.)

9. Heatings: up to 250℃,

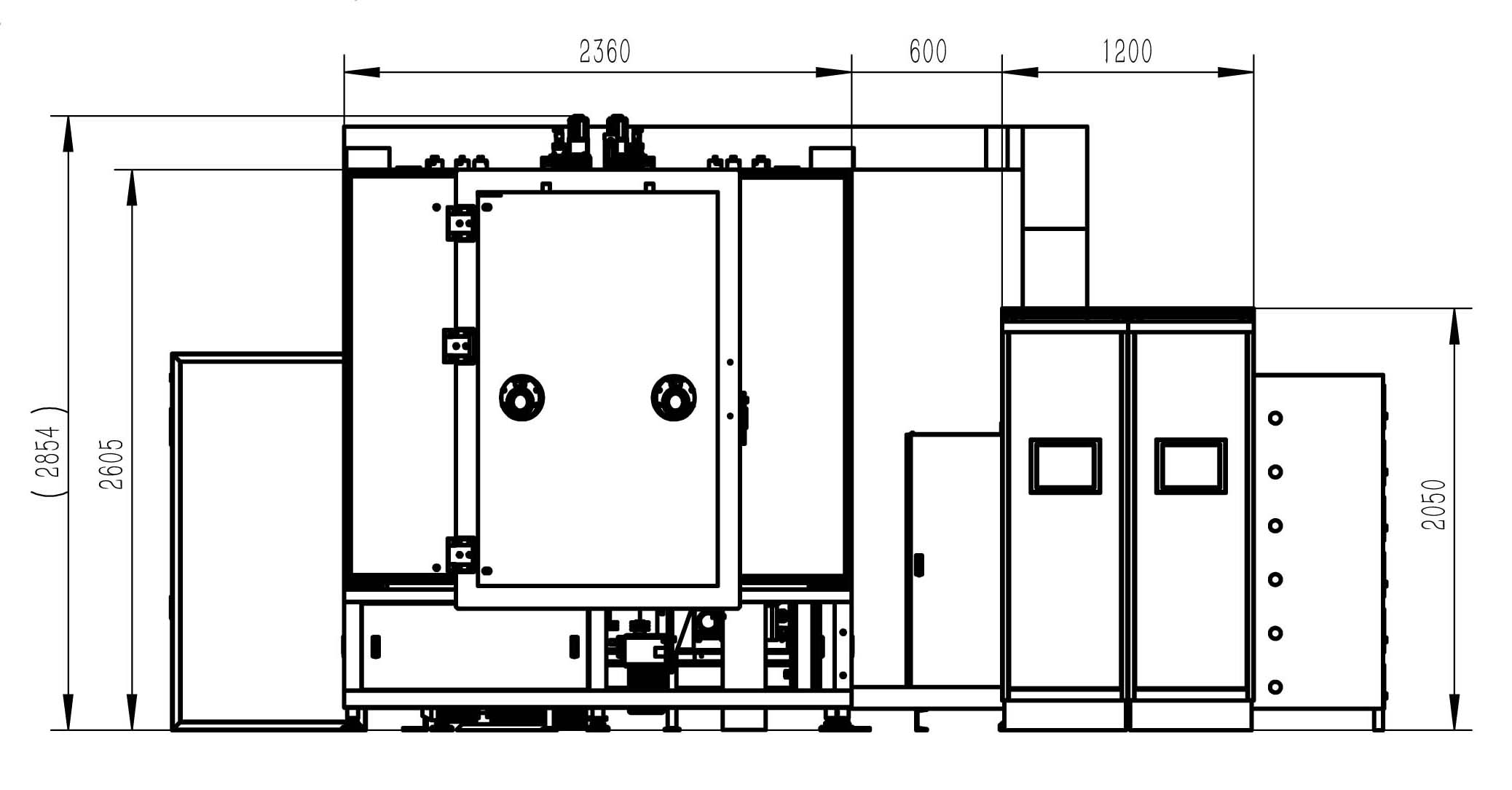

| Description | RTAC1600 |

| Standard Applications | Faucets, plumbings, furniture components, metal lamps, for high volume products |

|

Deposition Chamber

(mm) |

φ1600 * H1800 |

|

Maximum Loading

(kg) |

1000 |

|

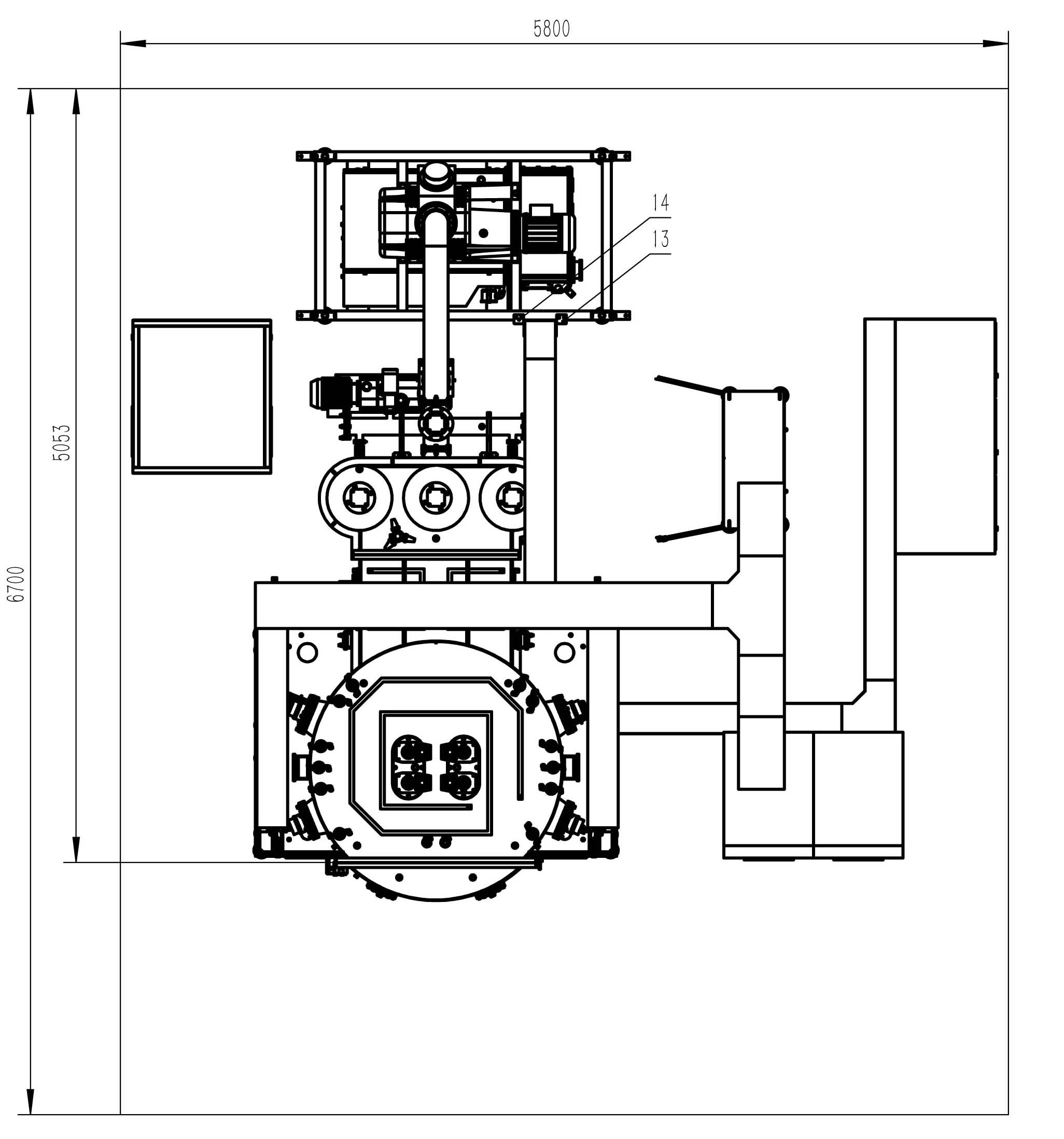

Central Driving

Effective Coating Area (mm) |

8: φ900*H1500

10:φ1000*H1500 |

|

Planetary Driving

Effective Coating Area (mm) |

8: φ350*H1400

10: φ290*H1400 |

|

Pulsed Bias Power

(KW) |

48 |

| Circular Arc Cathode (sets) | 18 |

| High Vacuum Pumps |

2* Diffusion Pumps or

4* Turbo Molecular Pumps |

| Backing Pumps | 1*SV630BF+1*WAU2001+1*TRP90 |

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.