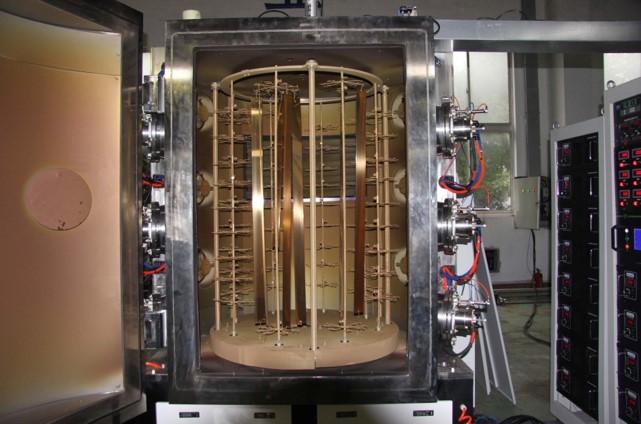

RTAC1400 model is the most popular and the most stable arc coating machine for PVD decorative coatings.

PVD (Physical Vapor Deposition) arc coating is a type of PVD coating process that is commonly used to apply decorative and functional coatings to various materials. Here's an overview of PVD arc decorative coating:

Coating Process:

Principle: PVD arc coating involves the use of an electric arc to vaporize a metal target material in a vacuum chamber. The vaporized metal atoms then condense on the substrate surface, forming a thin film coating.

Setup: The process takes place in a vacuum chamber where the substrate to be coated and the metal target are placed. The chamber is evacuated to create a low-pressure environment.

Arc Evaporation: An electric arc is generated between the target material (often a metal like titanium, chromium, or zirconium) and the substrate. The intense heat of the arc vaporizes the target material, creating a plasma of metal ions.

Coating Deposition: The metal ions travel to the substrate surface and condense, forming a thin film coating. The coating thickness can be controlled by adjusting parameters such as deposition time and target material evaporation rate.

Adhesion and Properties: PVD arc coatings typically exhibit excellent adhesion to the substrate, high hardness, good wear resistance, and aesthetic appeal, making them suitable for decorative applications.

Benefits

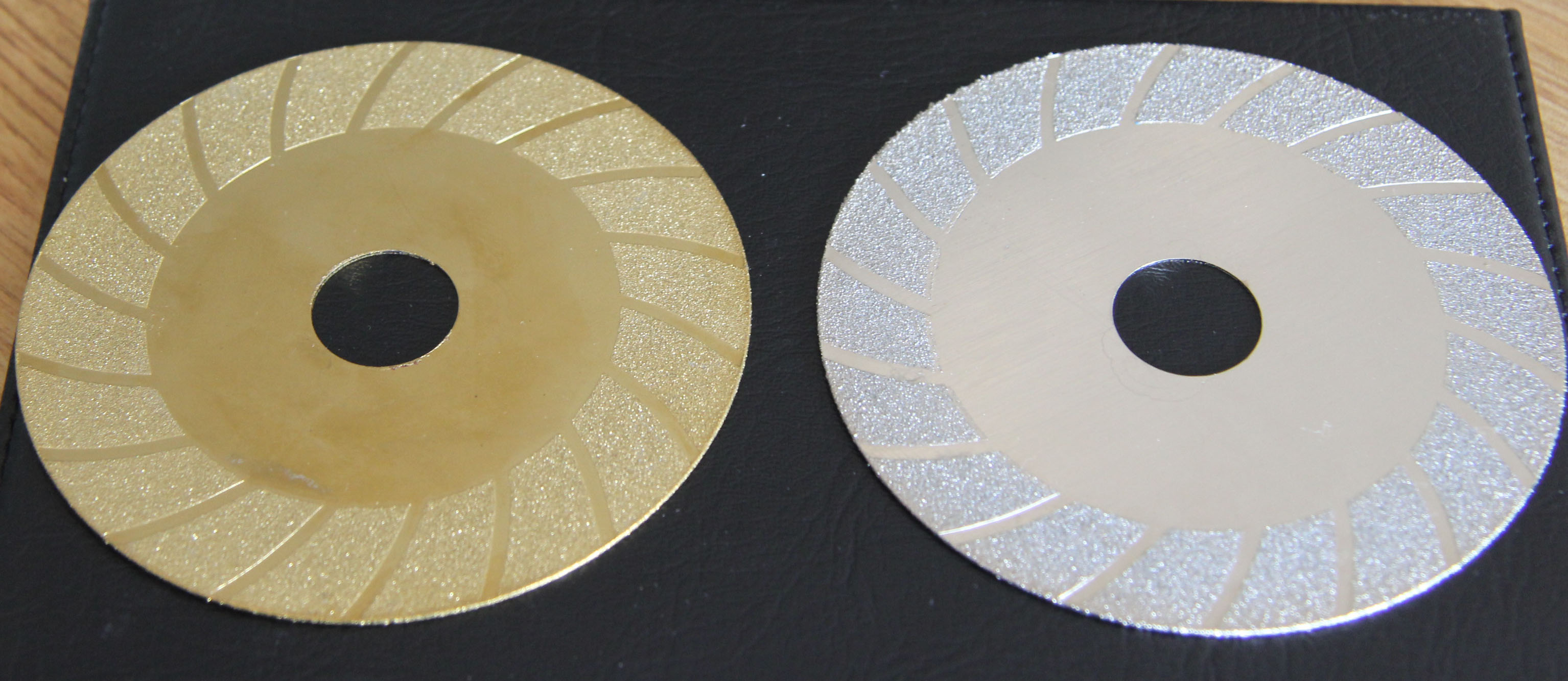

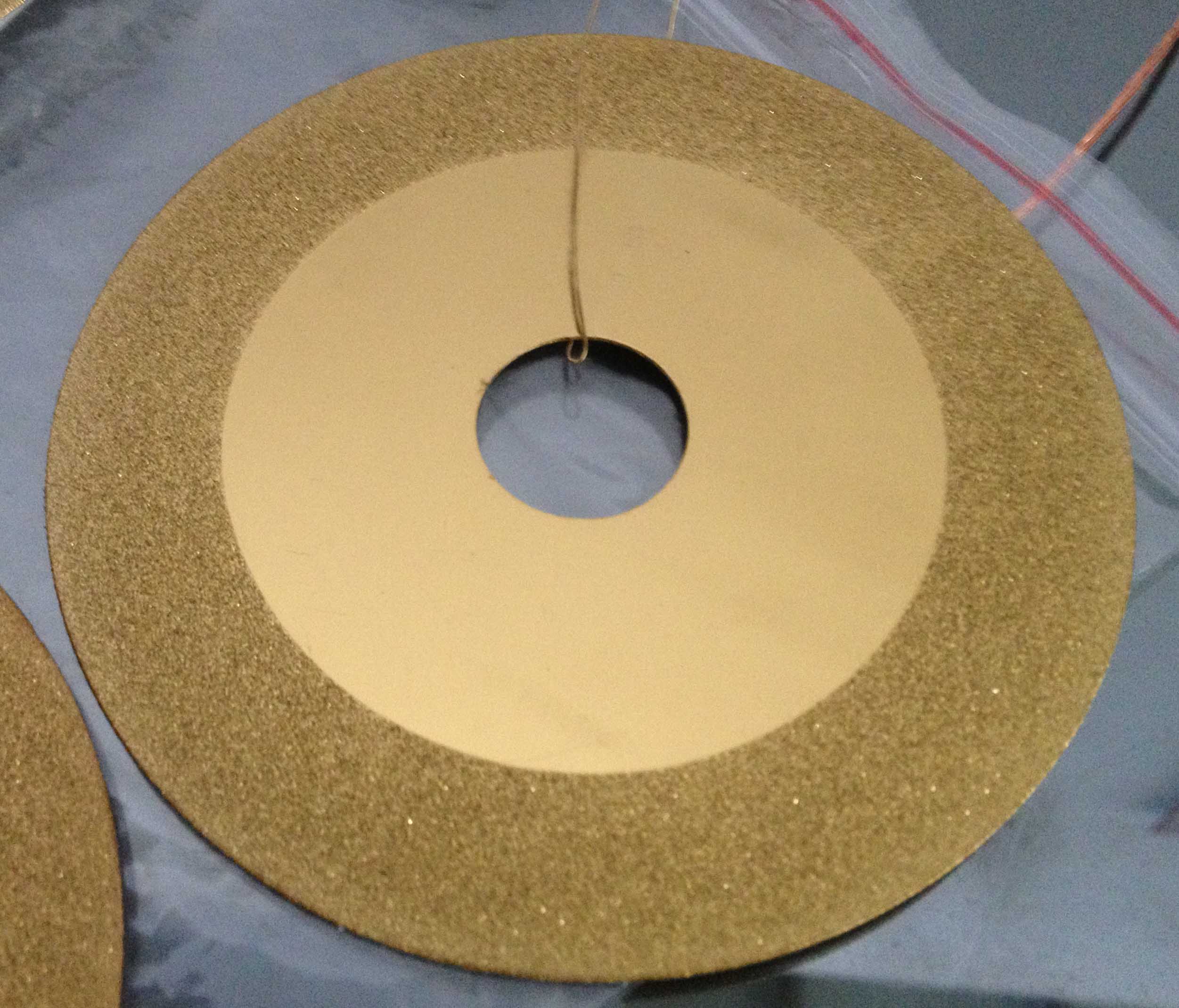

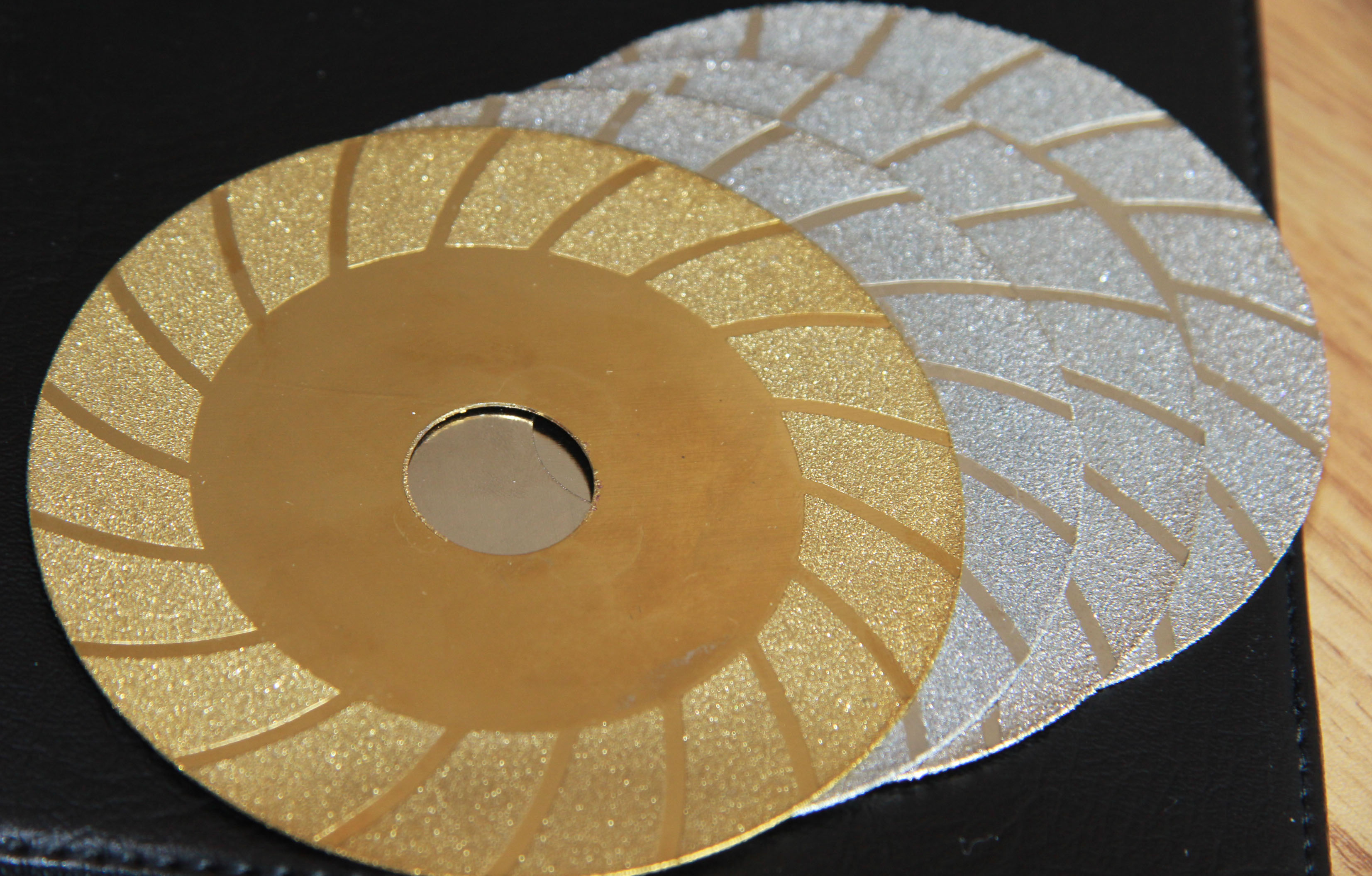

Decorative Finishes: PVD arc coatings can create a range of decorative finishes, including metallic colors like gold, silver, bronze, and black, enhancing the appearance of various products.

High Durability: These coatings offer excellent wear resistance and durability, making them suitable for applications where the coated surface is subjected to mechanical or environmental stresses.

Corrosion Resistance: PVD arc coatings can improve the corrosion resistance of substrates, protecting them from environmental factors such as moisture and chemicals.

Uniform Coating: The PVD arc process typically results in a uniform coating thickness and coverage, ensuring consistent quality across the coated surface.

Environmentally Friendly: PVD coatings are environmentally friendly compared to traditional plating processes, as they are free of harmful chemicals and produce minimal waste.

Applications

Consumer Electronics: PVD arc coatings are widely used in the consumer electronics industry for coating smartphone casings, watch bands, and other electronic devices to enhance their aesthetics and durability.

Automotive: These coatings are employed in the automotive industry for decorative trim parts, wheels, and accessories to provide a high-quality finish and protection against wear.

Architectural: PVD arc coatings are also utilized in architectural applications, such as coating door hardware, faucets, and furniture fittings for improved aesthetics and longevity.

In summary, PVD arc decorative coatings offer a versatile and high-quality solution for enhancing the appearance and functionality of a wide range of products, providing durable and attractive finishes for various applications.

PVD (Physical Vapor Deposition) decorative coatings offer a range of advantages across various industries and applications. Here are some of the key benefits of using PVD decorative coatings:

-

Aesthetic Appeal:

- PVD coatings can create a wide range of decorative finishes, including metallic, matte, glossy, and colored coatings, enhancing the visual appeal of products.

- These coatings can be customized to achieve different colors and effects, providing designers with creative options.

-

Durability:

- PVD coatings are highly durable and resistant to wear, abrasion, and corrosion, making them ideal for applications that require long-term performance.

- These coatings can extend the lifespan of products by protecting them from environmental factors and daily wear and tear.

-

Scratch Resistance:

- PVD coatings offer excellent scratch resistance, maintaining the appearance of surfaces even in high-traffic or abrasive environments.

- The hardness of PVD coatings helps protect the underlying material from scratches and damage.

-

Chemical Resistance:

- PVD coatings are resistant to many chemicals and environmental factors, making them suitable for applications where exposure to harsh substances is a concern.

- The chemical resistance of PVD coatings can help maintain the integrity and appearance of products over time.

-

Biocompatibility:

- Certain PVD coatings are biocompatible, making them suitable for medical devices, implants, and other applications where contact with the human body is required.

- Biocompatible coatings ensure that products are safe for use in medical and healthcare settings.

-

Environmentally Friendly:

- PVD coatings are applied in a vacuum environment without the use of harmful chemicals, making them an environmentally friendly coating option.

- The process produces minimal waste and does not release toxic substances into the environment.

-

Uniform Coating Thickness:

- PVD coatings provide a uniform thickness across the surface of the substrate, ensuring consistent performance and aesthetics.

- The precise control over coating thickness helps maintain the desired properties of the coated products.

Overall, PVD decorative coatings offer a combination of aesthetic enhancement, durability, and functional benefits, making them a popular choice for various industries, including automotive, aerospace, medical, and consumer goods.

|

MODEL |

RTAC-1400 |

|

MATERIAL |

Stainless Steel (S304) |

|

CHAMBER SIZE |

Φ1400*1600mm (H) |

|

CHAMBER TYPE |

Cylinder, vertical, single door |

|

SINGLE PUMP PACKAGE |

Rotary Piston Vacuum Pump |

|

Roots Vacuum Pump |

|

|

Roots Pump |

|

|

TECHNOLOGY |

Cathodic Arc Evaporation, Ion Plating |

|

POWER SUPPLY |

Arc sources power supply + Bias Power supply |

|

DEPOSITION SOURCE |

14 Cathodic Arc Sources |

|

CONTROL |

PLC+Touch Screen |

|

GAS |

Gas Mass Flow Meters |

|

SAFETY SYSTEM |

Numerous safety interlocks to protect operators and equipment |

|

COOLING |

Cooling Water |

|

CLEANING |

Arc Discharge |

|

POWER MAX. |

75 KW |

|

AVERAGE POWER CONSUMPTION |

35 KW |

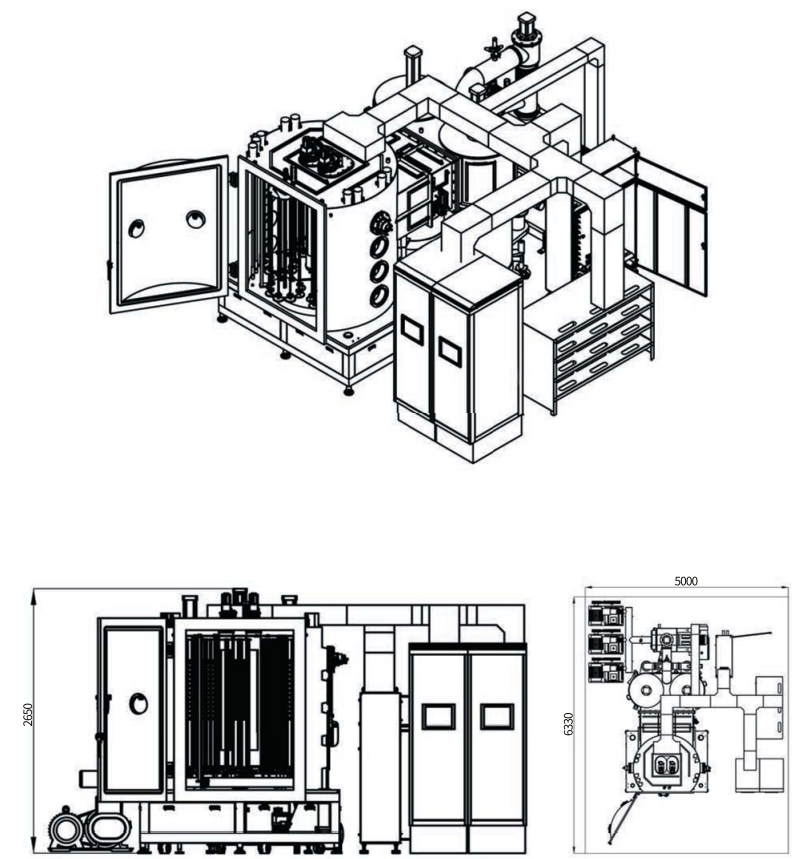

Layout

Machine Model: RTAC1400

Project Time: 2015

Project Location: China