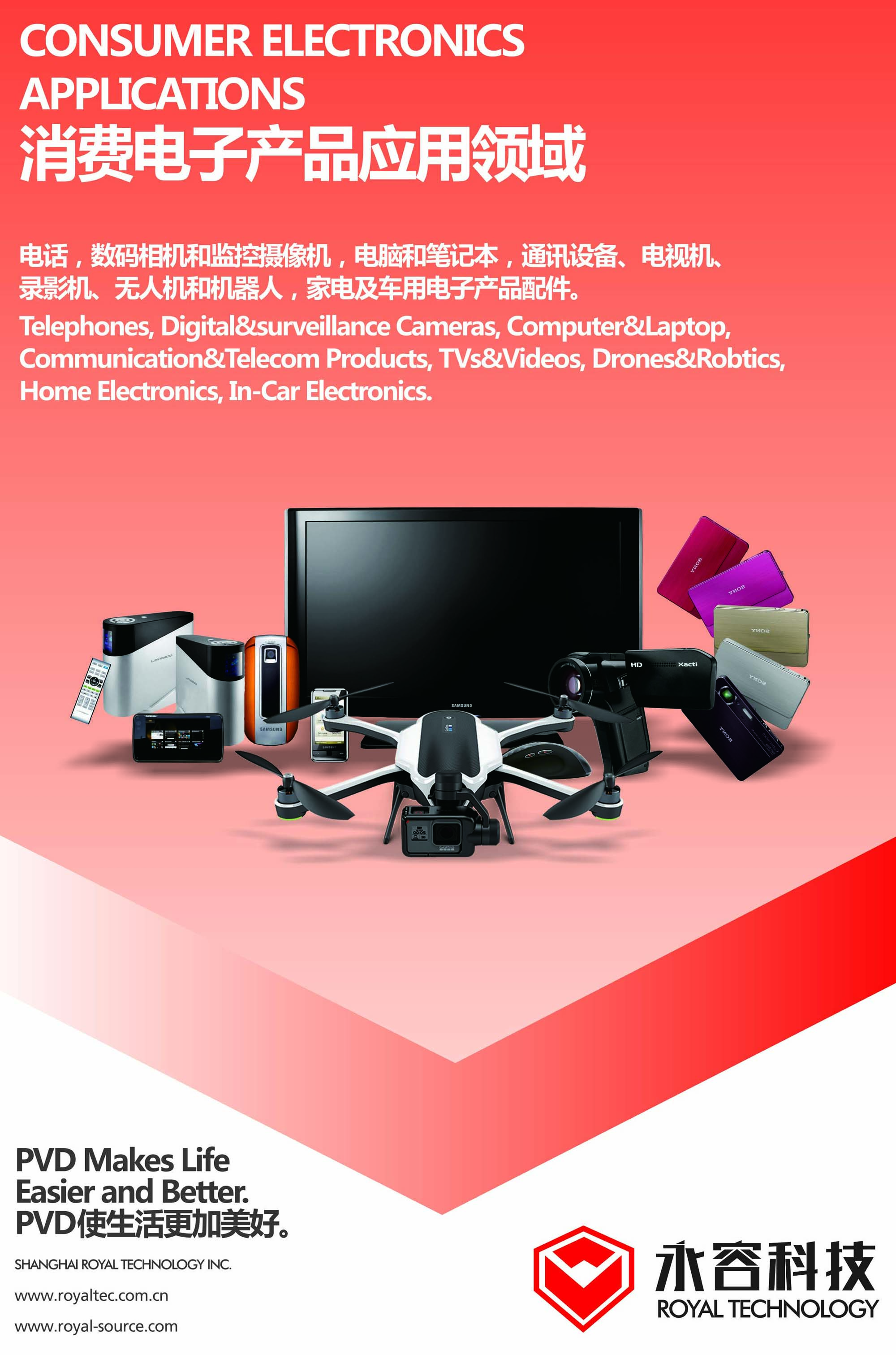

Physical Vapor Deposition (PVD) coatings are commonly used in consumer electronics to enhance the appearance, durability, and functionality of various devices. Here are some of the common applications of PVD coatings in consumer electronics:

Decorative Finishes:PVD coatings can be applied to give consumer electronics a decorative finish, such as gold, rose gold, or black finishes on smartphone casings, smartwatches, and laptop parts.

Scratch and Wear Resistance:PVD coatings can improve the scratch and wear resistance of surfaces on devices like smartphones, tablets, and wearables, ensuring that they maintain their appearance over time.

Corrosion Resistance:PVD coatings can protect electronic components from corrosion, which is especially important for devices that are frequently exposed to moisture or harsh environments.

Improved Conductivity:Certain PVD coatings can enhance the electrical conductivity of components in consumer electronics, leading to better performance and efficiency.

Anti-Reflection Coatings:PVD coatings can be used to reduce glare and reflections on screens, improving visibility and user experience on devices like smartphones, tablets, and laptops.

Biocompatibility:PVD coatings can be used in wearable devices to make them more biocompatible, reducing the risk of skin irritation or allergic reactions.

Thermal Management:PVD coatings can be applied to improve the thermal management of electronic components, helping to dissipate heat more effectively and prevent overheating.

Overall, PVD coatings play a crucial role in enhancing the aesthetics, durability, and performance of consumer electronic devices, making them more attractive and functional for users.

Royal Technology has developed functional coatings for consumer electronics products: EMI shielding ( Electromegnetic Interference) and NCVM ( Non-Conductive Vacuum Metalizing ) Equipment.

NCVM process are majoy applied with Mobile Phones, Laptop, Computer and other electronic products. It gives a metallic coating surface, but non-conductive property to avoid from affecting the communication quality of eletromegnetic wave.

EMI process is specially designed for various electronic devices to avoid from interference of electromagnetic. Both thermal evaporation & sputtering processes could achieve high efficiency and good uniformity of coating thickness.