Machine Model: RT1000-DLC

Technology: PVD magnetron sputtering deposition of DLC film

Built Time: February , 2022

Location: Switzerland

Installation & Testing: 3 days

Commissioning & Training: 14 days

As we all know, most famous high luxury watches are SWISS MADE, especially for the mechanical watches parts like high precision bearings, cores, watch case, watch bands etc. at least 60% of components are made in Switzerland.

Its extremely strict manufacturing processes and quality inspection standards make final products perfect.

Since March of 2021, we delivered 3 rounds coated samples, SwissMeccompany delivered samples to France Laboratory to inspect if the technical properties are qualified:

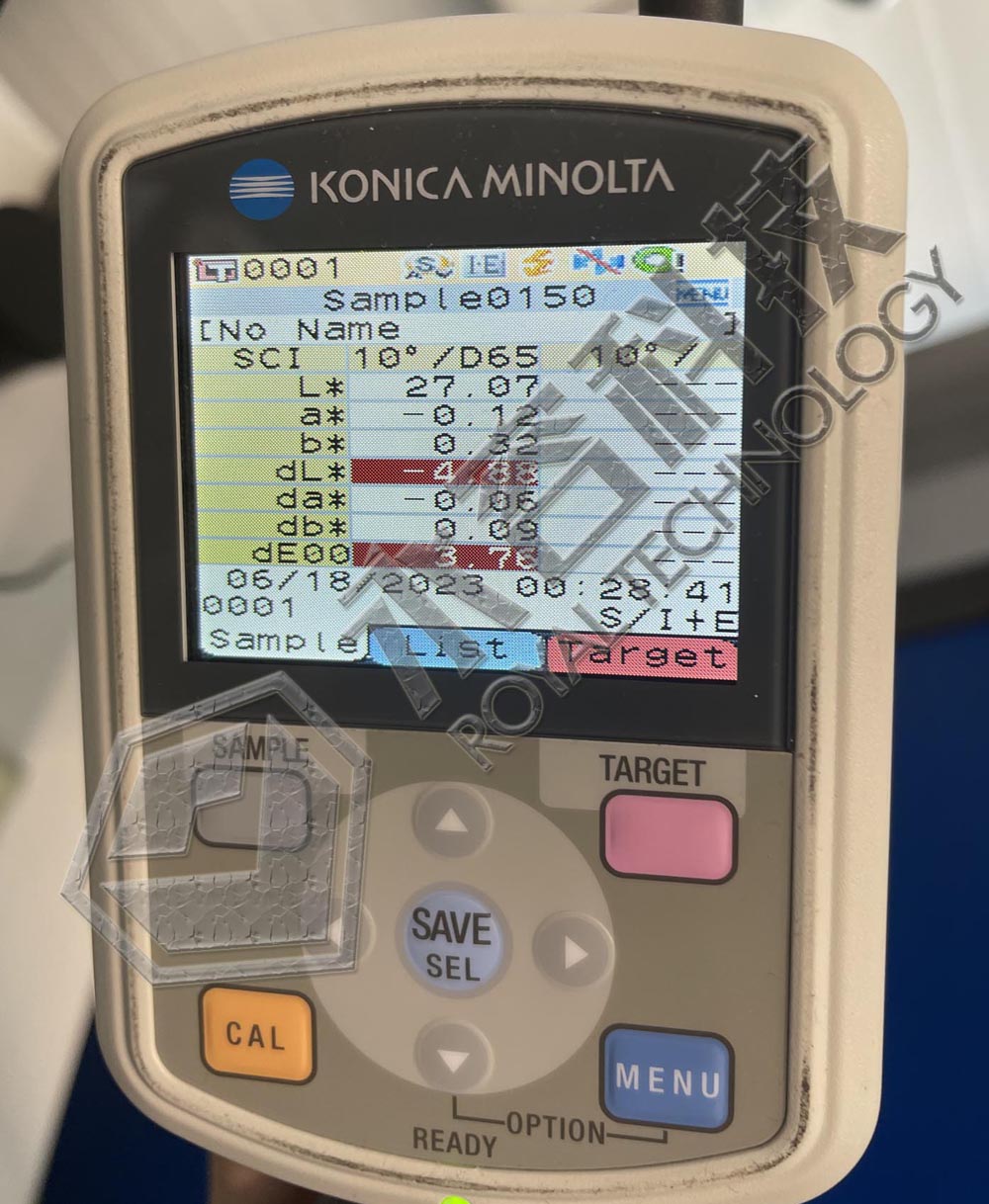

1. Color: LAB, dE<1.5

2. UV Testing

3. Thermal shock

4. Salt Spray

5. Sweat synthetic

6. Tropical climate

7. Abrasion

8. Impact resistance

9. Scotch Test

We insist on the concept: the coating process (recipes) determines machine’s configurations, machine configurations determines price. The SwissMec project is the perfect interpretation of this statement. From sample’s testing to machine delivery, installation and training in the SwissMec company, it took almost ONE year.

“We are grateful for Ms. Celine’s support and cooperation on this project. Her patience and faith in us encouraged us to finish this project in the end. But due to Covid19 restrictions, our Chinese Engineer can not go to the customer's site. We are looking forward to providing more training onsite soon."

Royal Technology