Ceramic dielectric filters play a crucial role in 5G base stations, helping to manage and filter radio frequency signals efficiently. Here is an overview of their key features and functions:

Features of 5G Base Station Ceramic Dielectric Filters:

Dielectric Material:

Ceramic materials like alumina (Al2O3) or aluminum nitride (AlN) are commonly used due to their high dielectric constants and low loss tangents at RF frequencies.

Royal Technology has successfully developed the coating process and PVD vacuum metallizing machine.

Depositing copper coatings on ceramic dielectric filters using the sputtering deposition technique is a common method in the manufacturing of RF components for various applications, including 5G base stations. Here's an overview of the process:

Sputtering is a physical vapor deposition (PVD) technique where energetic ions bombard a target material (copper in this case), causing atoms to be ejected and deposited onto a substrate (ceramic dielectric filters).

Preparation:

The ceramic filters are cleaned and pre-treated to ensure a clean surface for the adhesion of the copper coating.

Loading:

The prepared filters are placed in the sputtering chamber, and the chamber is evacuated to create a vacuum environment.

Target Preparation:

A solid copper target is mounted in the sputtering system. The target material is bombarded with high-energy ions, causing copper atoms to be ejected and deposited on the substrate.

Sputtering Process:

A high-voltage electrical field is applied to the copper target, creating a plasma discharge and causing copper atoms to be sputtered onto the ceramic filters.

Film Growth:

Copper atoms deposit on the substrate, forming a thin copper film. The film thickness can be controlled by adjusting deposition parameters such as power, pressure, and deposition time.

Uniformity Control:

Parameters liketarget-to-substrate distance,rotation of the substrate, and deposition rate are controlled to ensure uniform coating thickness across the entire surface of the ceramic filters.

Adhesion Promotion:

Adhesion promoters or inter-layers may be used to enhance the adhesion between the copper coating and the ceramic substrate.

Post-Deposition Treatment:

Annealing or other post-deposition treatments may be performed to improve the properties of the copper coating, such as adhesion, conductivity, and stability.

Quality Control:

The deposited copper coating is subjected to quality control measures such as adhesion tests, film thickness measurements, and micro-structural analysis to ensure the coating meets the required specifications.

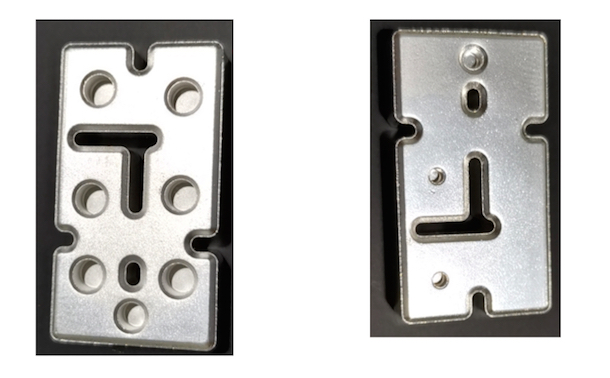

PVD silver plating PVD copper sputtering deposition

By utilizing copper sputtering deposition on ceramic dielectric filters, manufacturers can produce RF components with precise copper coatings that enhance signal transmission, filtering capabilities, and overall performance in applications such as 5G base stations.