R2R (Roll-to-Roll) web vacuum metallization for plastic films is a common industrial process used to apply thin metallic coatings onto flexible plastic substrates in a continuous roll-to-roll manner. This process enhances the barrier properties, decorative appeal, and functionality of plastic films for various applications such as packaging, electronics, and specialty products.

Aluminum and Copper Vacuum Metallization

Optical Film Coatings

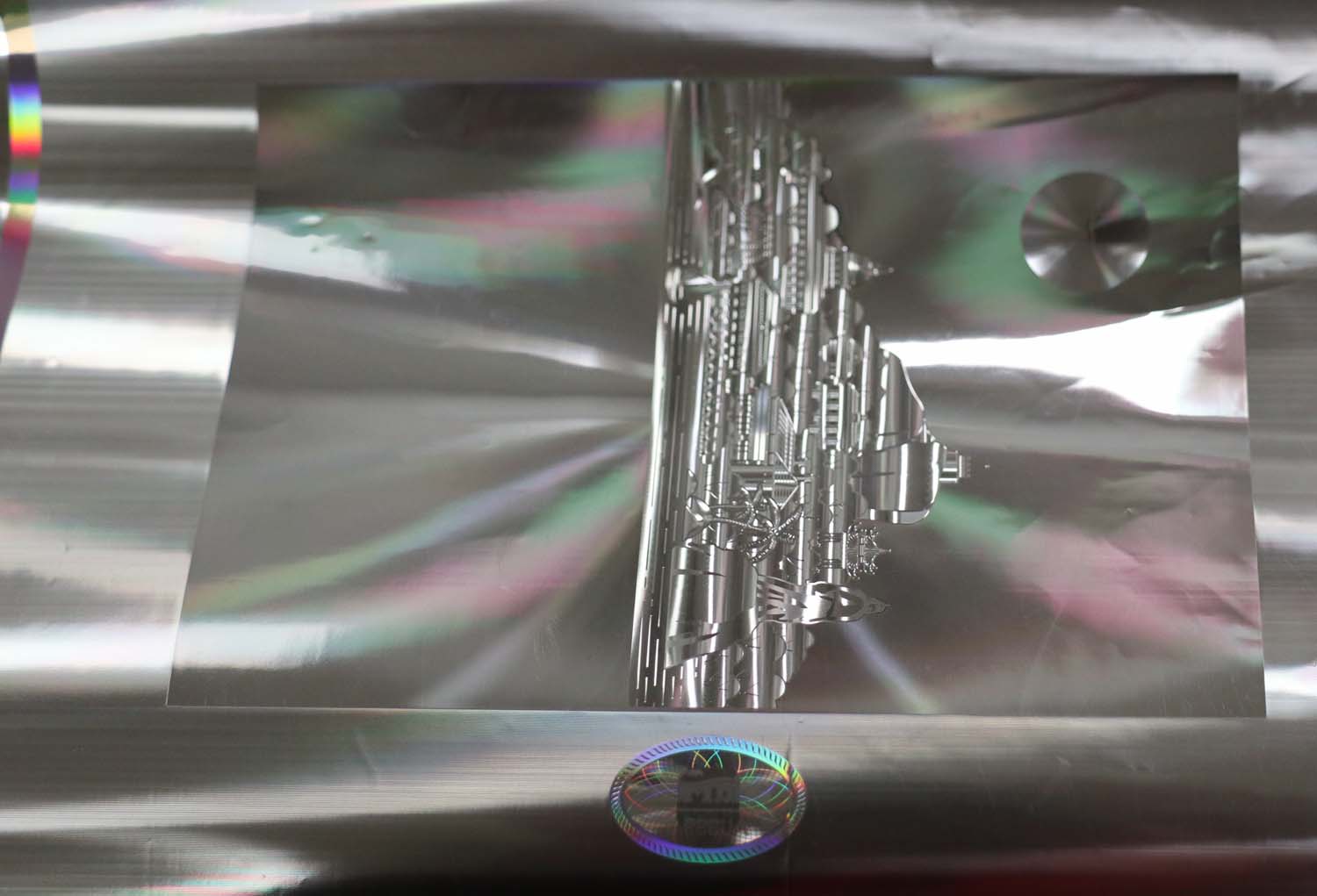

Components of R2R Web Vacuum Metallization System for Plastic Films:

1.Unwinder: Where the plastic film roll is fed into the machine.

2.Vacuum Chamber: Where the metallization process takes place under controlled vacuum conditions.

3.Metal Source: The material (e.g., aluminum, copper, etc.) used to create the thin metallic layer.

4.Evaporation System: Converts the metal source into vapor for deposition onto the plastic film.

5.Substrate Heating System: Helps improve adhesion and film quality.

6.Rewinder: Collects the metallized plastic film as a continuous roll after the coating process.

Process Overview:

1.Web Handling: The plastic film roll is unwound and fed into the machine.

2.Vacuum & Metallization: The plastic film passes through a vacuum chamber where the metal source is evaporated. The metal vapor condenses onto the surface of the plastic film, forming a thin metallic layer.

3.Substrate Heating: Heating the plastic film can improve adhesion and film quality.

4.Rewinding: The metallized plastic film is wound onto a roll for further processing or converting into final products.

Advantages of R2R Web Vacuum Metallization for Plastic Films:

·Enhanced Barrier Properties: Improves the barrier properties of plastic films against moisture, oxygen, and other external factors.

·Decorative Finishes: Provides a metallic appearance for decorative packaging and specialty products.

·Functional Coatings: Offers functional properties such as conductivity or reflectivity for specialized applications.

·Cost-Effective Production: Enables high-speed, continuous production for cost-effective manufacturing.

·Versatility: Compatible with various types of plastic films and a range of metals for diverse applications.

R2R web vacuum metallization for plastic films is a versatile and efficient process that enhances the performance and aesthetics of plastic film materials, making them suitable for a wide range of applications across different industries.