Built Time: 2018

Location: Malaysia

Please contact us for more specifications. Royal technology is ready for servicing you at any time.

High Temperature Vacuum Degassing Machine for Molds PVD hard coating pretreatment. Royal Technology designed and manufactured the vacuum degassing system for industrial production application. It is designed with heaters up to over 500℃ to get the injection mould or cutting tools degassing in the vacuum chamber in high pressure environment before PVD hard coating process. It can improve the quality of products and shorten the processing cycles during PVD hard coating process.

As a customized machine, Royal Technology listened to customers demands carefully and response quickly with proper proposals. From negotiation till the machine used for massive production, only 4 months.

It shortens the PVD hard coatings cycle time and improve the productivity efficiently.

How does it work?

Alternate methods can be used to remove or minimize the quantity of gas bubbles, but vacuum technology used in degassing applications can improve the quality of products and shorten processing cycles.

Remove Gases

Vacuum Degassing removes trapped gases from compounds such as resins or epoxies which become entrapped in the mixture when mixing the components. If not removed before the material cures, gas bubbles will cause defects such as nodules, cavities, or hollows in the finished cast. Vacuum chamber degassing can improve the quality of products and shorten processing cycles.

When a mixture is put into a vacuum degassing chamber and the air pressure above it reduced, i.e. evacuated, the gas bubbles which formed at atmospheric pressure expand and rise to the surface where they burst and the gas released is pumped away.

A high-temperature vacuum degassing machine is a specialized equipment used in various industries, including metallurgy, electronics, and materials processing, to remove impurities and trapped gases from materials under high-temperature and low-pressure conditions. Here's an overview of the machine and its operation:

Purpose: The primary function of a high-temperature vacuum degassing machine is to remove dissolved gases, impurities, and volatile elements from materials such as metals, alloys, and plastics to improve their quality, mechanical properties, and performance.

Operation:

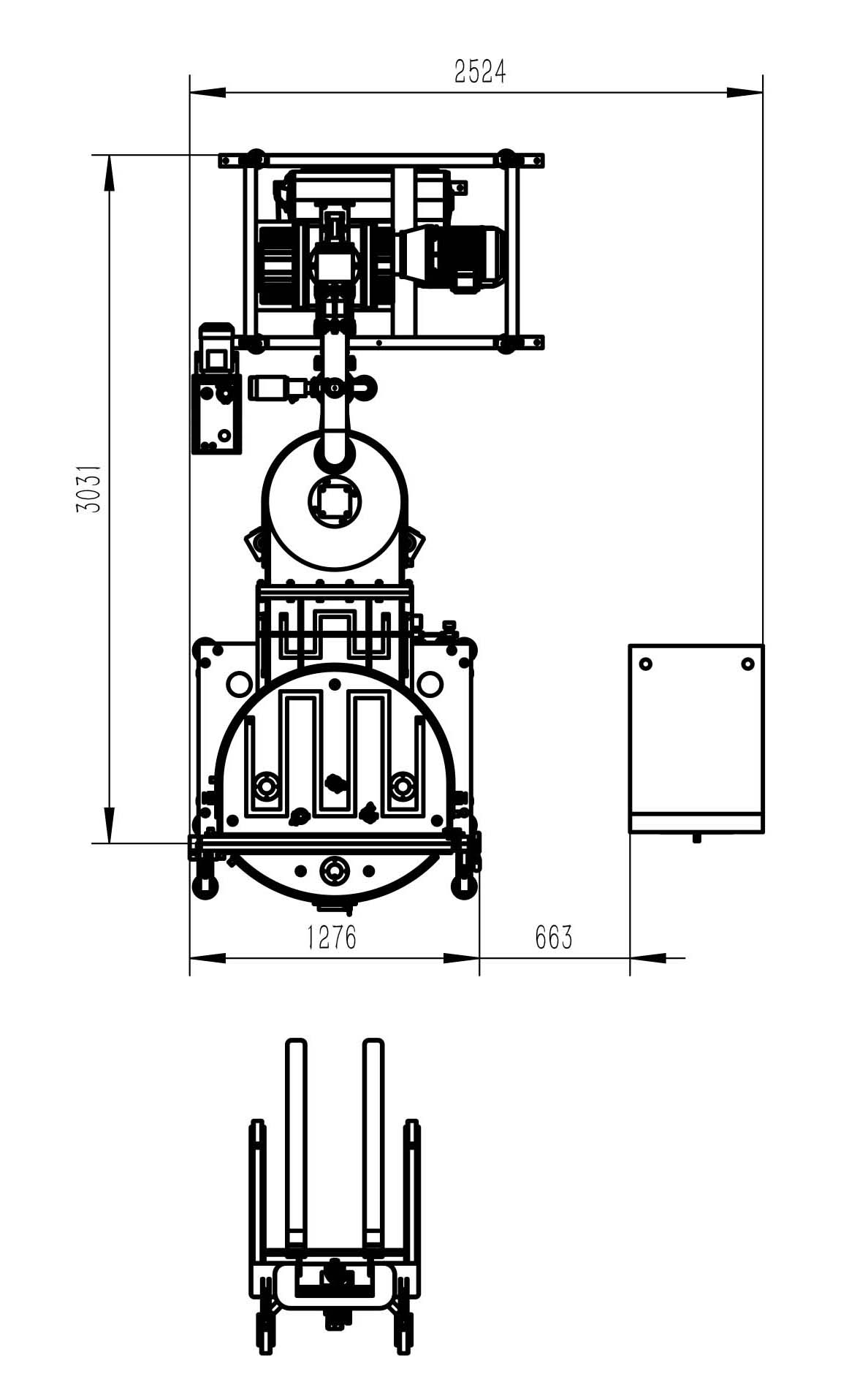

Chamber: The machine consists of a vacuum chamber capable of withstanding high temperatures.

Heating System: It is equipped with a heating system to raise the temperature of the material to be degassed to a specific level.

Vacuum System: The machine has a vacuum pump or system to create and maintain a low-pressure environment within the chamber.

Gas Removal: As the material is heated under vacuum, the trapped gases and impurities are released and evacuated from the chamber.

Temperature Range: High-temperature vacuum degassing machines are designed to operate at elevated temperatures, typically ranging from several hundred to over a thousand degrees Celsius, depending on the material being processed.

Applications:

Metallurgy: Used in the production of steel, aluminum, and other alloys to remove dissolved gases like hydrogen, oxygen, and nitrogen that can affect the material properties.

Plastics Processing: Applied in the production of high-performance plastics to eliminate volatile components and enhance the material's mechanical properties.

Electronics: Utilized in semiconductor manufacturing to degas materials used in the production of electronic components to ensure high purity and reliability.

Materials Research: Employed in materials research labs to study the behavior of materials under high-temperature and low-pressure conditions.

Benefits:

Improved Material Quality: Vacuum degassing helps to enhance the mechanical properties, purity, and performance of materials.

Consistent Results: Provides a controlled environment for degassing processes, ensuring consistent and reproducible outcomes.

Reduced Defects: Helps in reducing defects in materials caused by trapped gases and impurities.

Conclusion:

A high-temperature vacuum degassing machine is a crucial tool in various industries where the removal of impurities and gases from materials is essential to ensure the quality and performance of the final products. By creating a controlled environment of high temperature and vacuum, these machines play a vital role in improving material properties and meeting stringent quality standards.

Design Advantages

Technical Specifications

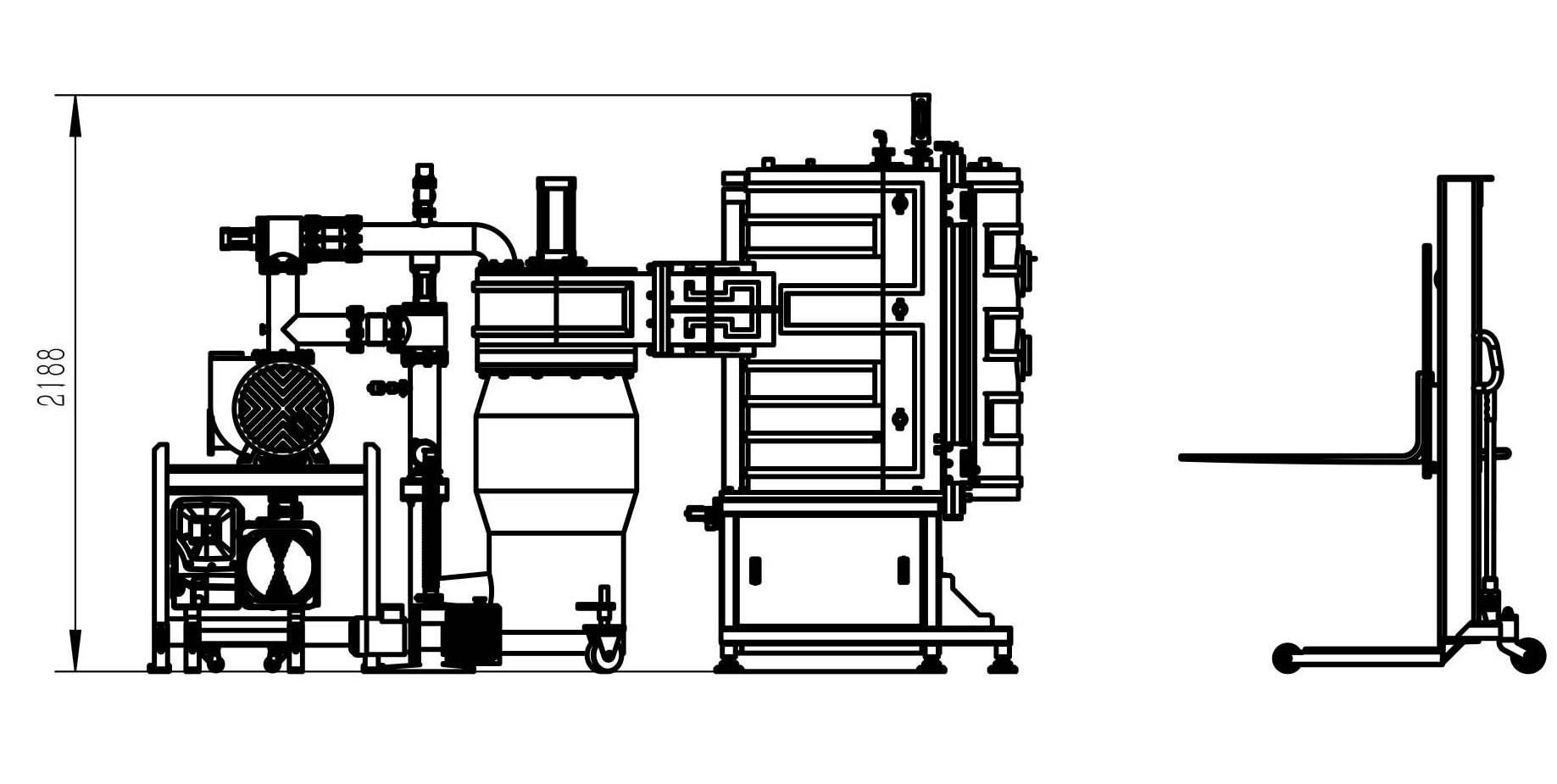

Model: RTVF1000

Chamber Height (mm): 1200

Chamber Diameter (mm): φ1000

Vacuum Chamber Door: 1 set, U Shape

Rotary Rack: 1 set, central driving

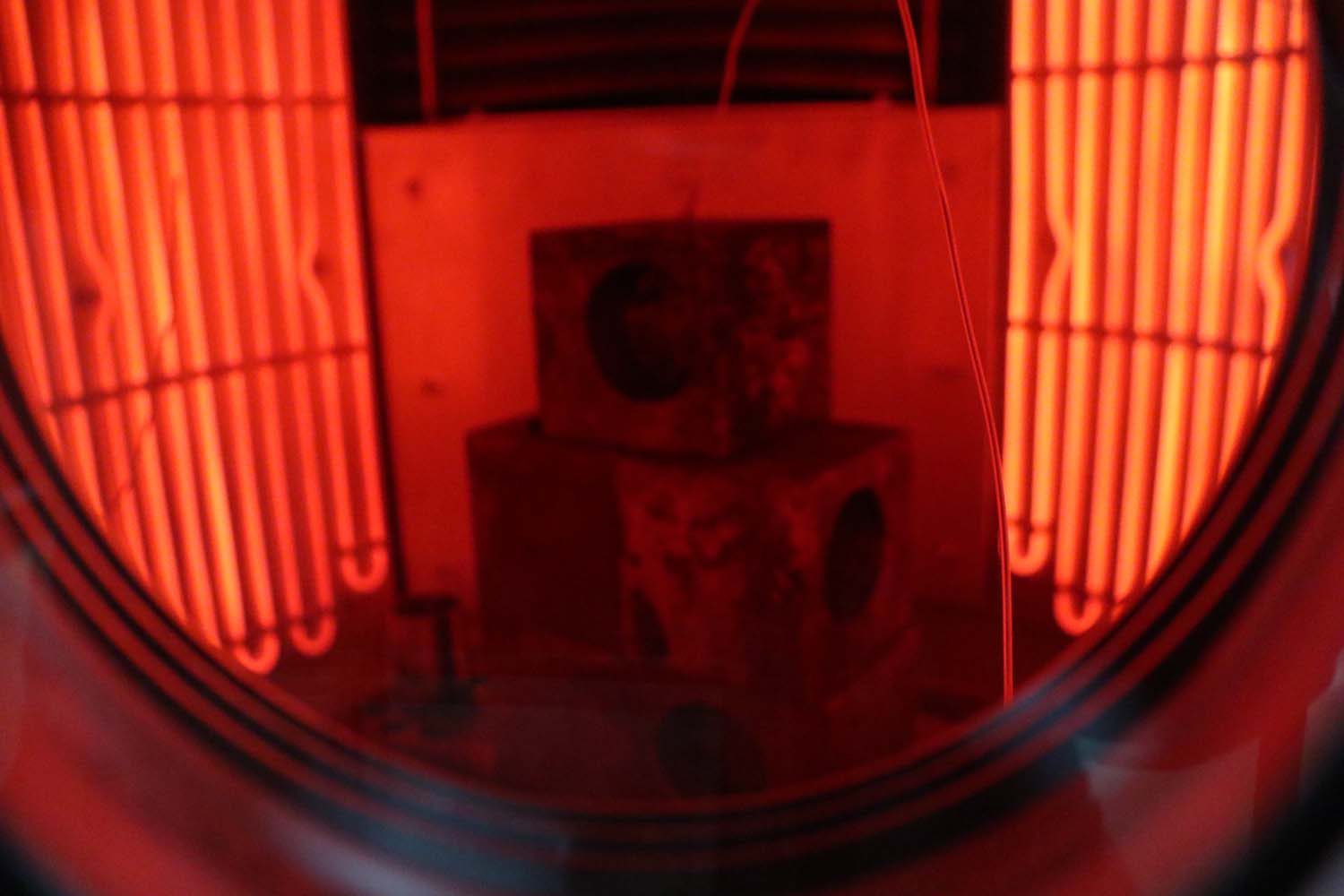

Heating System:

With average thermocouple control.

Three pieces blocks simulation, 1 small and 2 big.

Max. Temperature 500℃, from room temperature till 500℃ ,

Less than 30 minutes. (clean, without loading)

Cooling System:

Inclusive MFC channel for He/Ar injection, a fast cooling down process.

Capacity:

Max. Loading weight: 1000kgs

Vacuum Pumps:

High vacuum diffusion pump: 7000L/S

Roots pump: 300L/S

Mechanical pump: 280m3/hr

Holding Pump: 36m3/hr

Installation Area ( L x W x H) mm: 3000*3000*2800

Layout