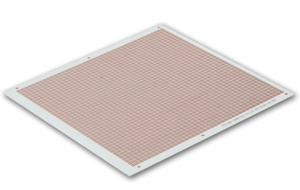

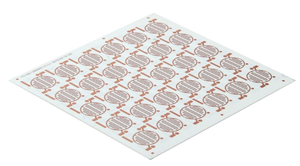

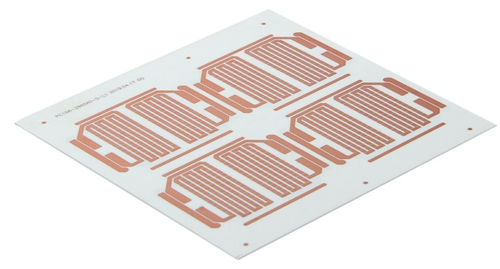

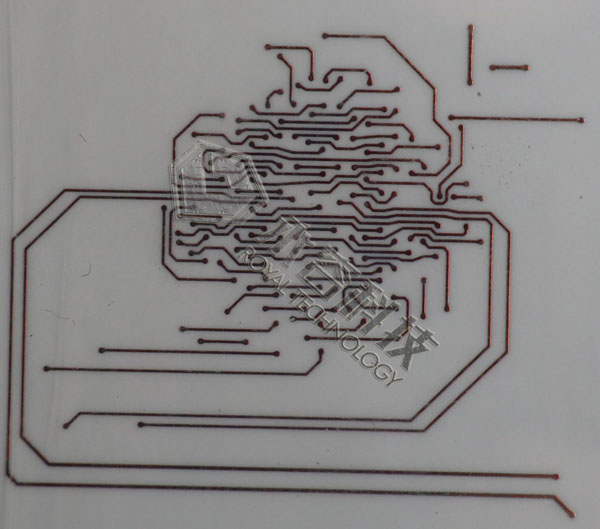

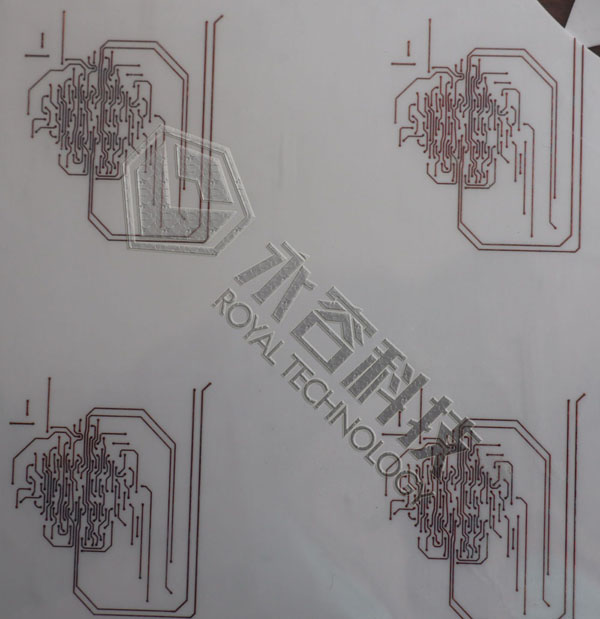

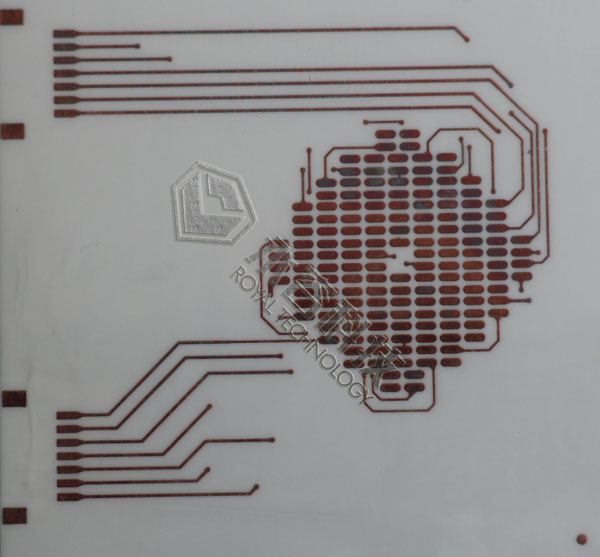

Direct Plated Copper Metallized Substrate and Its Application on Microwave Circuits Board. A direct plated copper (DPC) metallized substrate technique is introduced and characterized in this article. The proposed DPC metallized substrate provides the main advantages of excellent thermal management and high-frequency characteristics.

The direct plated copper (DPC) process on metallized ceramic substrate was originally created to replace the direct bonded copper (DBC) process because of its better electrical, thermal and mechanical performances.

1. Compared to DBC, DPC provides a very strong bond strength between the Al2O3/AlN substrate and the copper metal, due to the use of a thin film bonding layer.

2. DPC also has a good ability in thickness control for the copper layer, from very thin to very thick.

The DPC process- Direct Plating Copper is an advanced coating technique applied with LED and semiconductors in electronic industry. One typical application is by using Ceramic Radiating Substrate method. Copper conductive film deposition on Aluminum Oxide (Al2O3), AlN substrates with PVD vacuum sputtering technology, has above all one big advantage compared to traditional manufacturing methods: DBC, LTCC HTCC, which is much lower production costs. Royal Technology’s team collaborated with our customer to develop the DPC process successfully applying PVD sputtering technology.

Typical Applications of Ceramic DPC:

- HBLED

- Substrates for solar concentrating cells

- Power semiconductor packaging including automotive motor control

- Hybrid and electric automobile power management electronics

- Packages for RF

- Microwave devices

Only to name a few, for more applications, please contact Royal Tech.

Large Capacity

Flexible Modules Design

Precised Manufacturing

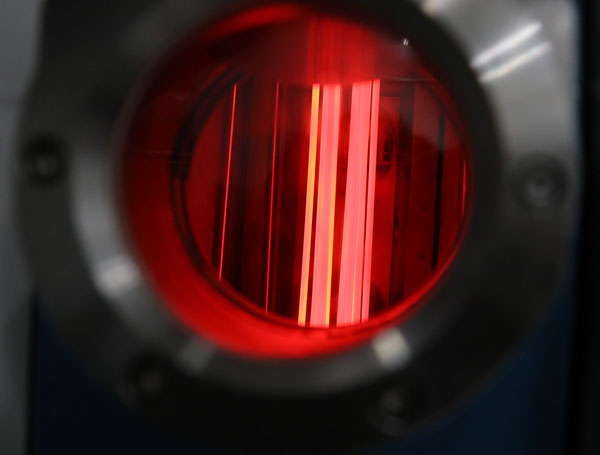

The DPC Sputtering system is the upgraded version of the original model, the newest system has several advantages:

Highly Efficient Process

1. Double sided coating is available by turnover fixture design

2. Up to 8 standard planar cathode flanges for multiple sources

3. Large capacity up to 2.2 ㎡ ceramic chips per cycle

4. Fully Automation, PLC+Touch Screen, ONE-touch control system

Lower Production Cost

1. Equipped with 2 sets magnetic suspension molecular pumps, fast starting time, free maintenance

2. Maximum heating power

3. Octagonal shape of chamber for optimum space using, up to 8 arc sources and 4 sputtering cathodes for fast deposition of coatings

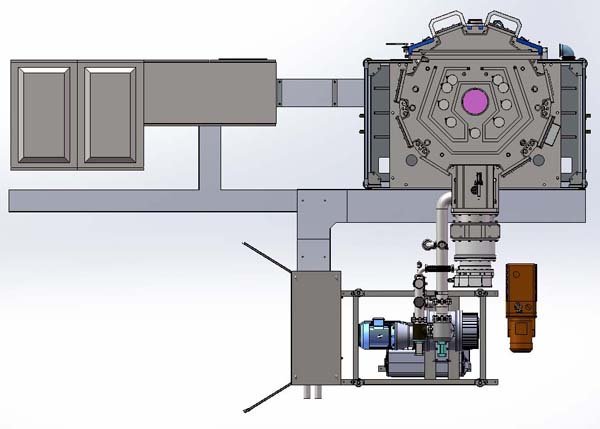

Model: RT1200-DPC

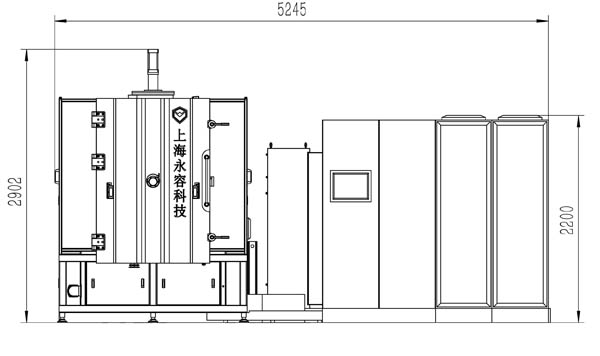

Chamber Height (mm): 1500

Chamber diameter (mm): φ1200

Sputtering Cathodes Mounting Flange: 4

Ion Source Mounting Flange: 1

Arc Cathodes Mounting Flange: 8

Satellites (mm): 16 x Φ150

Pulsed Bias Power (KW): 36

Sputtering Power (KW): DC36 + MF36

Arc Power(KW): 8 x 5

Ion Source Power (KW): 5

Heating Power (KW): 36

Effective Coating Height (mm): 1020

Magnetic Suspension Molecular Pump: 2 x 3300 L/S

Roots Pump: 1 x 1000m3/h

Rotary Vane Pump: 1 x 300m3/h

Holding Pump: 1 x 60m3/h

Capacity: 2.2 ㎡

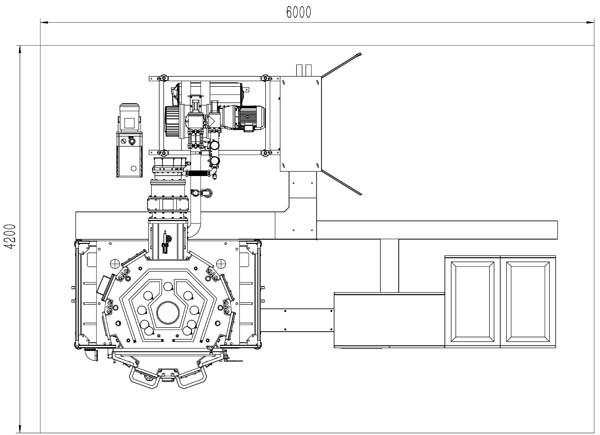

Installation Area ( L x W x H) mm: 4200*6000*3500

Layout

Machine Model: RT1200-DPC

Technology: PVD+PECVD

Location: China

Application: Ceramic (Al3O2, AlN), Glass, and Si substrates