Conventional gold coatings on glassware are by aluminum vacuum metallization combine the thermal curing line. In 2020, Royal Technology developed an advanced coating technology to generate 2-sides gold colors on glassware directly without spraying painting processes ( pre/post coatings), which is ion plating technology- arc evaporation.This coating method is completely get rid of the spraying paintings, environmentally friendly, green technology, besides it reduces the investment of production line and labor cost for manufacturers.

PVD Coating glassware with a two-sided gold coating using ion plating is a specialized process that can provide a luxurious and durable decorative

finish. Ion plating, also known as ion beam sputtering or ion-assisted deposition, is a PVD technique that involves bombarding the coating material

with ions to improve the film's properties and adhesion.

Here's how the process of applying a two-sided gold coating on glassware using ion plating typically works:

Surface Preparation: The glassware surface needs to be thoroughly cleaned and prepared before the coating process. This involves cleaning,

degreasing, and sometimes etching the glass to create a rougher texture for better coating adhesion.

Ion Plating Chamber: The glassware is placed inside an ion plating chamber, which is a vacuum environment. The chamber is evacuated to create

a high vacuum condition.

Coating Material Preparation: In this case, gold is the desired coating material. Gold is loaded into a crucible or target inside the ion plating chamber.

Ion Bombardment: The process begins by introducing an inert gas, typically argon, into the chamber. The gas is ionized to create a plasma.

The plasma then bombards the gold target, causing gold atoms to be ejected from the target surface.

Film Deposition: The gold atoms released from the target travel as a vapor and condense onto the glassware's surface, forming a thin gold film.

The ionized argon gas accelerates and assists the deposition process, improving the film's density, adhesion, and overall quality.

Rotation or Tilting: To achieve a two-sided gold coating, the glassware may be rotated or tilted during the deposition process.

This ensures that both sides of the glassware receive an even and uniform coating.

Control of Thickness and Color: The thickness of the gold coating can be controlled by adjusting the deposition time and rate. This allows for

customization based on the desired appearance and requirements. Different deposition parameters can also be employed to achieve variations

in color and finish, such as rose gold or yellow gold.

Post-Coating Treatment: After the ion plating process, the coated glassware may undergo additional treatments, such as annealing or sealing,

to enhance the coating's durability, scratch resistance, and overall performance. These treatments help ensure the longevity of the gold coating.

Coating glassware with a two-sided gold coating using ion plating can provide an elegant and high-quality finish. It offers improved adhesion,

durability, and resistance to wear compared to traditional coating methods. This process is commonly used for high-end glassware, decorative items,

and luxury products that require a prestigious and eye-catching appearance.

If we use the Spraying paining + Aluminum metallization process do can generate a double-sides gold color result, but the adhesion is weak

and more complicated process, it makes the labor cost and production cost is increased.

In Nov. 2020, we received the request from middle east customer: double-sides looks gold and not use the spraying painting process.

After several cycles experiments, we found the proper coating process with strong adhesion.

Glass jars and glass cups gold coating

Royal technology provides you not only the coating system but the total coating solutions, we offer you turnkey-service.

Advantages

Both inside & outside seeing through is Gold color

- Many bright colors of final finishings

- Excellent scratch resistance

- Enables longer life of products

- Environmentally-friendly process

- Robust and high volume design machine

Main Features

- Standardized, modular design and fabrication

- PS electrical enclosure, designed and manufactured strictly following CE standards

- Operating software program in IPC is exclusive developed by Royal Technology, each set of machine is ready for system upgrading

- One-Touch automatically coating process is available

- Designed With 2 sets trolley and racks systems can push in/pulling out of chamber flexibly, to improve the productivity.

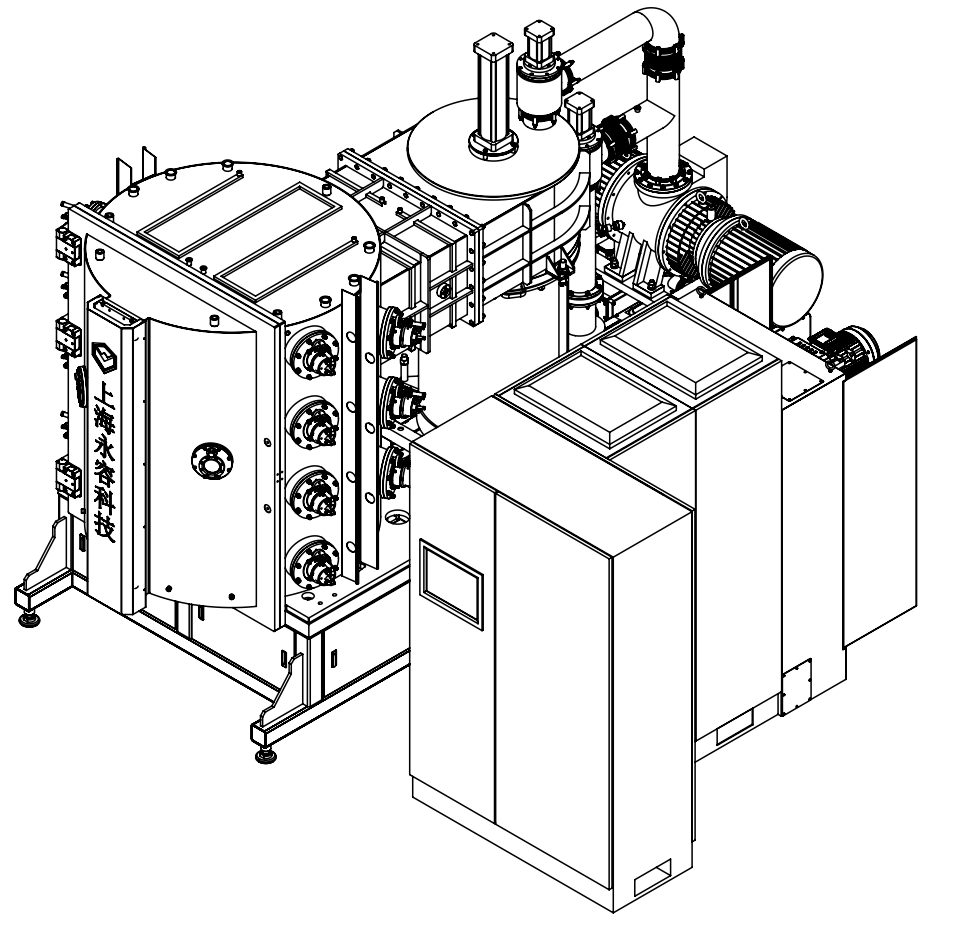

General Information

-

Arc ( Ion Plating ) series equipment consists of: vacuum chamber, vacuum pumps, arc sources, spindle & jack, jigs structure, heating & cooling,

water & gas (distribution), electrical control & operation systems, substrate carrier etc. - Benefits: easy to operate, compact foot print, low cost of owner ship, fast substrate exchange.

- Coating Types: metal & alloy coatings, multi layers coatings.

- Coating Colors: gold, black, brown, grey, Chrome colors etc

- Substrates: stainless sheets and tubes, metal alloys, glass, ceramic materials

- Coatings Advantages: high shiny and bright colors, strong adhesion & excellent scratch protection.

Technical Specifications

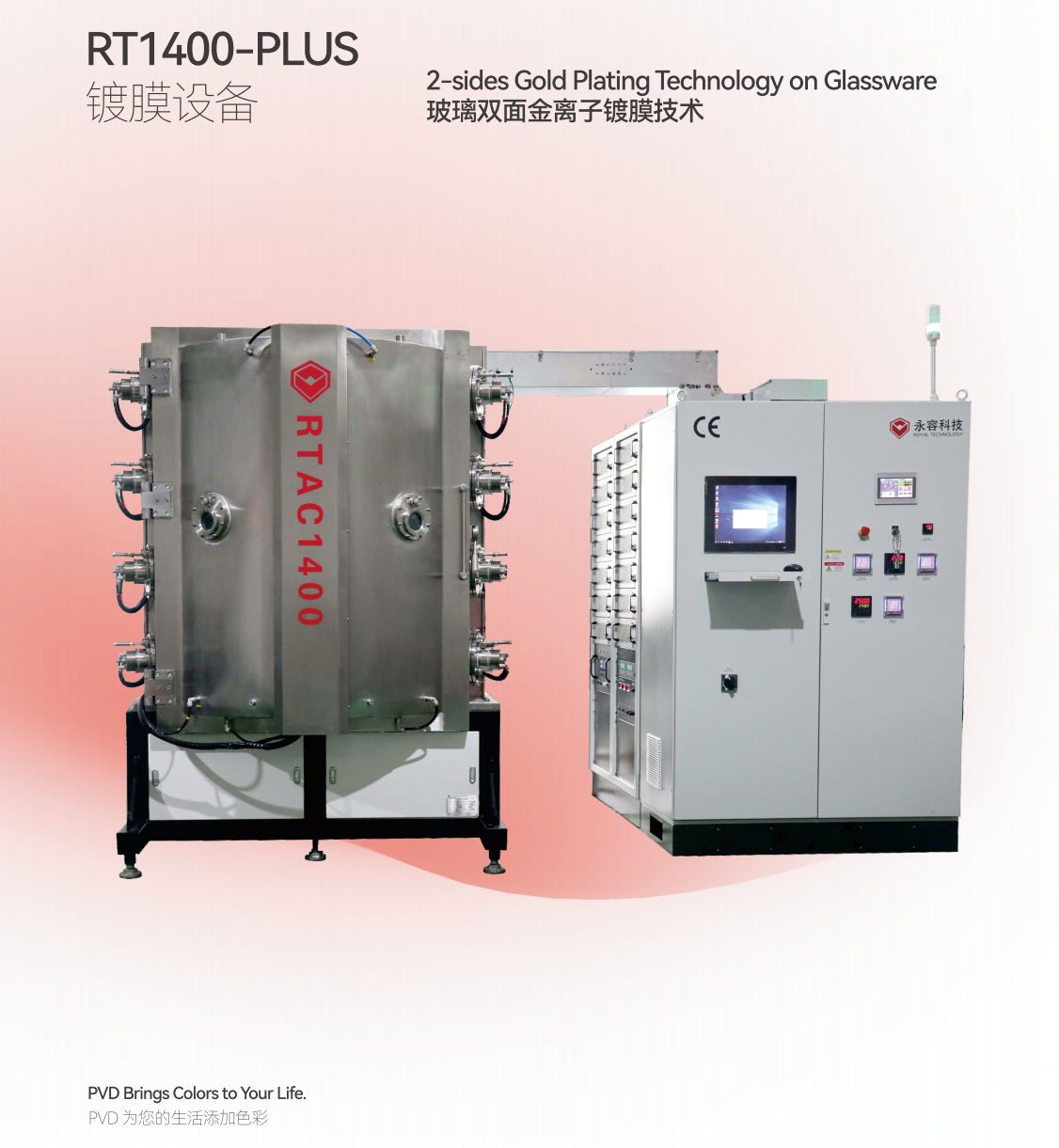

| MODEL | RT1400-PLUS |

| MATERIAL | Stainless Steel (S304) |

| CHAMBER SIZE | Φ1400*1600mm (H) |

| CHAMBER TYPE | Cylinder, vertical, front opening door |

| SINGLE PUMP PACKAGE | Rotary Piston Vacuum Pump |

| Roots Vacuum Pump | |

| Holding Pump + DP or TP | |

| TECHNOLOGY | Cathodic Arc Evaporation |

| POWER SUPPLY | Arc sources power supply |

| DEPOSITION SOURCE | 14 Cathodic Arc Sources |

| CONTROL | Siemens PLC+IPC |

| GAS | Gas Mass Flow Meters of 4 sets for Ar, N2, O2, C2H2 |

| SAFETY SYSTEM | Numerous safety interlocks to protect operators and equipment |

| COOLING | Recycle Cooling Water |

| CLEANING | Bias Power |

| POWER MAX. | 90KW |

|

AVERAGE POWER

CONSUMPTION |

40 KW |

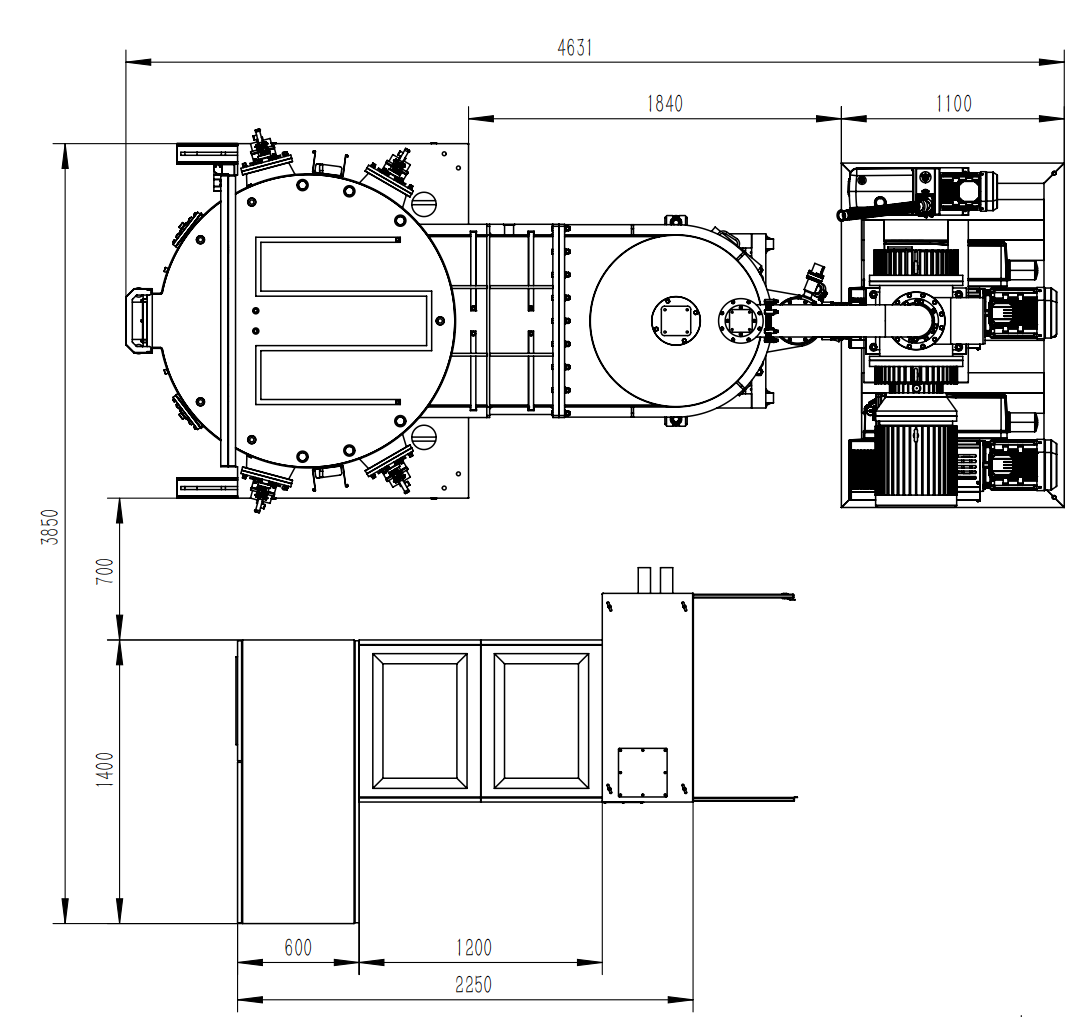

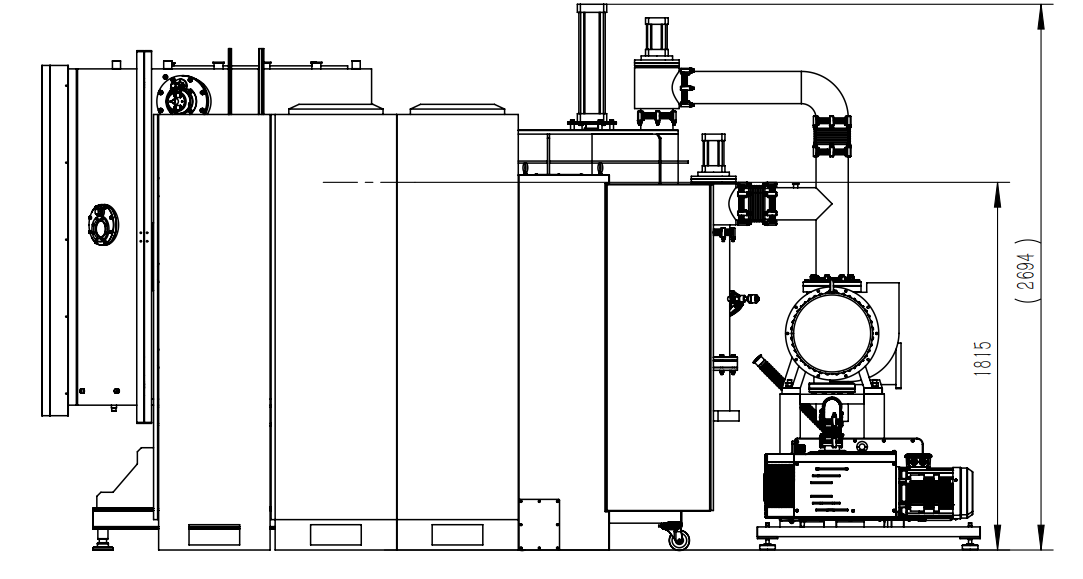

Layout

If you are interested in this technology and machine, please call us today to receive a FREE consultation.

Machine Model: RT1400-PLUS

Built Time: 2021

Location: Turkey