Physical Vapor Deposition (PVD) techniques can be utilized to deposit antibacterial coatings on various substrates.

Medical Devices: PVD antibacterial coatings are commonly used on medical devices and equipment to reduce the risk of healthcare-associated infections.

Touch Surfaces: Coating touch surfaces in public spaces, such as door handles, elevator buttons, and handrails,with antibacterial layers can help maintain hygiene and reduce the spread of pathogens.

Food Packaging: Antibacterial coatings on food packaging can help prolong the shelf life of food products by inhibiting bacterial growth.

Public Transport: Coating surfaces in public transport vehicles with antibacterial layers can help create a more hygienic environment for passengers.

By utilizing PVD techniques to deposit antibacterial coatings, surfaces can be made resistant to bacterial contamination,contributing to improved hygiene and safety in various applications.

Are antibacterial surfaces a technological breakthrough?

A study conducted by the Battelle organization forecasts that antibacterial surfaces and germ-resistant coatings will be an important technological breakthrough in household products. Homeowners are looking for new cleansers that provide lasting protection on kitchen and bathroom surfaces.

The demand for antibacterial coatings on frequently used surfaces has long existance. With the rising of public health and domestic hygiene awareness, decorative coatings on SS and ceramic products, such as taps, door handles, hand rails, tiles, faucets, bathroom fittings with antibacterial properties may attract more attention from consumers than ever.

“After a half year of research and development, the test results eventually turned out excellent,” said Zhou Xin, the marketing director, “adding only several minutes based on traditional PVD decorative coatings, the products will be able to kill 99.99% of E. coli and S. aureus bacteria after 24 hours without affecting other important properties.”

|

Analysis & Test Result (By Guangdong Detection Center of Microbiology ) Dec. 2020 |

The test microorganism | The average plate count of blank control samples recovered over 24h(cfu/pieces) | The average plate count of test samples recovered over 24h(cfu/pieces) | Antibacterial rate (%) |

| Testing Material: stainless steel, brushed | Escherichia Coli (AS1.90) | 9.2×106 | <20 | >99.99 |

| Staphylococcus aureus (AS1.89) | Coating Colors: black, chrome, TiN gold, Rose gold | 8.8×105 | <20 | >99.99 |

| The above testing report is only for reference, actual value might be various when substrate material, testing method changes. | ||||

- Kitchen implements like SS sinks, SS houseware

- SS flatware: spoon, fork, knife

- Sanitaryware: faucets, bathroom fittings

- Door handles

- Ceramic tiles

- Glassware for food storage

- Medical instrument and more

Brass alloy, zinc alloy, Stainless steel sanitaryware

SS410 Kitchenware Ceramic Tiles

Door handles

- High antibacterial effect and long lasting

- Low production cost

- Green coating technology

- Scratch resistance

- Corrosion & wear resistance

Key Features

- Plug-in integrated design system

- IPC control & operation module

- Available for remote monitoring and diagnosis

- Flexible, ready for upgrading

- Multiple cathodes for fast depostion coatings

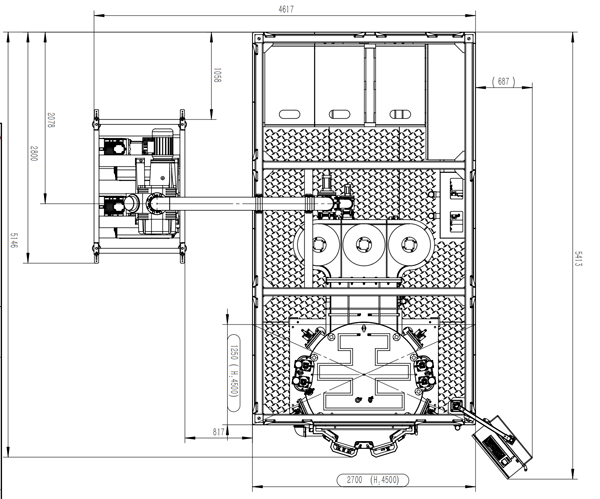

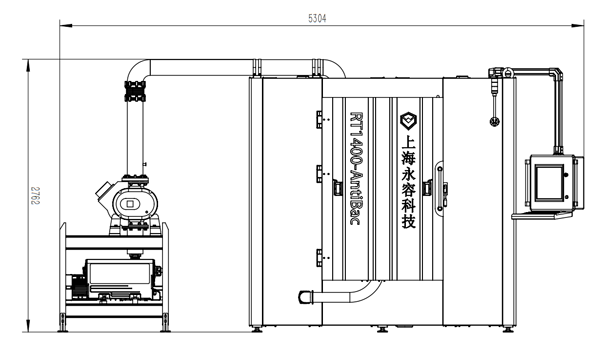

Machine Model: RT1400-Antibac

|

Effective Coating Size (mm) |

Max. Loading (kgs) |

Deposition Sources |

Pulsed Bias Power (KW) |

Sputtering Power |

Heater Power (KW) |

Power Consumption (KW) |

Installation Space (L*W*H) mm |

|

6*φ370

8*φ300 |

500 | Arc and sputtering cathodes | Max. 36 | Max. 36 | Max. 18 |

Max. 90

Average: 50 |

6700*5800*3500 |

We are ready to share this advanced technique with our customers, anyone is interested in providing the antibacterial finishing as an high added-value on your products,

please contact us today.