Low Temperature Arc Vapor Deposition (LTAVD) is a technique within the Physical Vapor Deposition (PVD) process that allows for the deposition of metal coatings onto substrates, particularly heat-sensitive materials like plastics, at relatively low temperatures compared to traditional PVD methods, enabling coating without damaging the substrate material; it occurs in a vacuum chamber using a low voltage arc to generate the vapor for deposition.

What is LTAVD

Low temperature arc vapor deposition (LTAVD) is a new addition to the field of cathodic arc plasma physical vapor deposition processes.

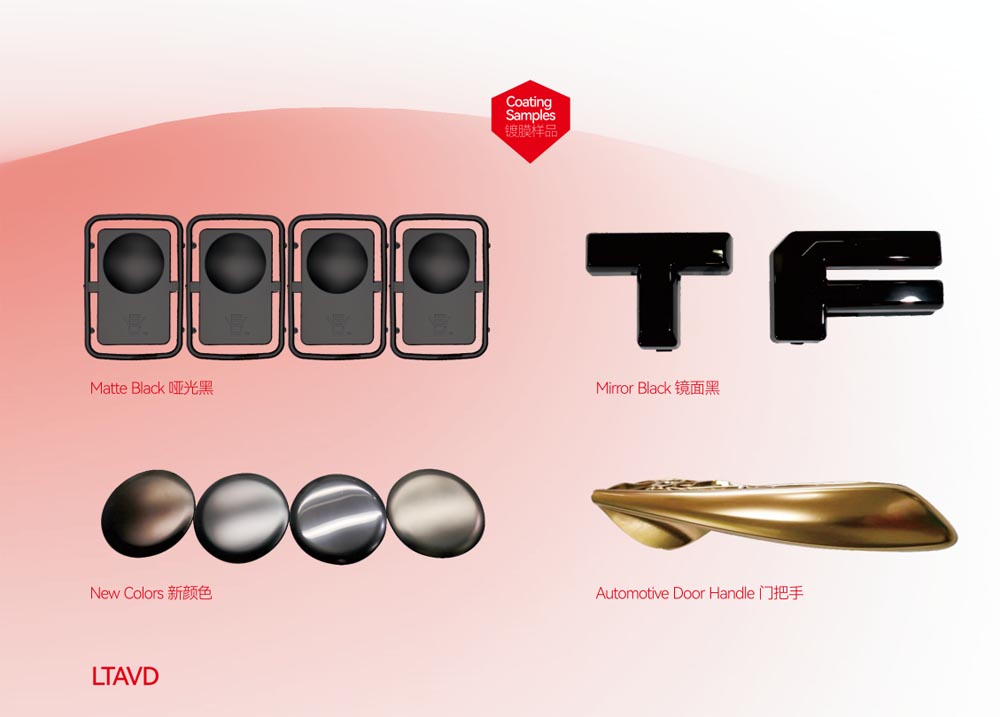

With its ability to deposit coatings at room temperature, LTAVD has been utilized on a commercial basis in applying coatings to plastics to address electrical, optical, thermal, corrosion/oxidation, mechanical and decorative requirements. LTAVD is a dry process and hence is environmentally safe.

Applications:

Plastic parts and other low-temperature resistance materials like ABS, ABS+PC, PPS, PEK, polyimide, polyetherimide, fluorocarbons (Teflon), ABS, polyurethane, polypropylene, polyethylene, PVC, polyester, nylon, phenolics, polycarbonate, epoxies and other plastics and intermetallic compound as well as many ceramics

Consumer electronics: cellphone, computer, television, cameras;

Home appliances: bathroom and kitchen fixtures; air conditioners, washing machine, vacuum cleaners etc.

Automotive industry: plastic interior trims and exterior trims, LOGO

Coatings Properties:

Extremely durable and scratch resistance;

High density;

Excellent adhesion;

Nano thin film which enable a wide variety of designs, no issues of dimensions, tolerances after coating.

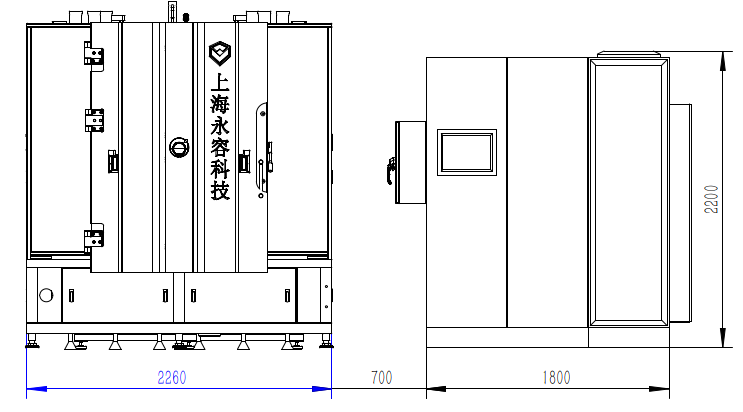

Model: RT1600-LTVAD

Deposition Chamber (mm): Stainless Steel 304

φ1600 x H1600 (63” x 63”)

Effective Coating Zone (mm): φ1350 x H1250

Load Mass (kg): 500 ~ 1000

Number of Satellites (mm): 6 or 8 or 10 for option

Pulsed Bias Power(KW): 36

Arc Cathode Power (KW): 14*5

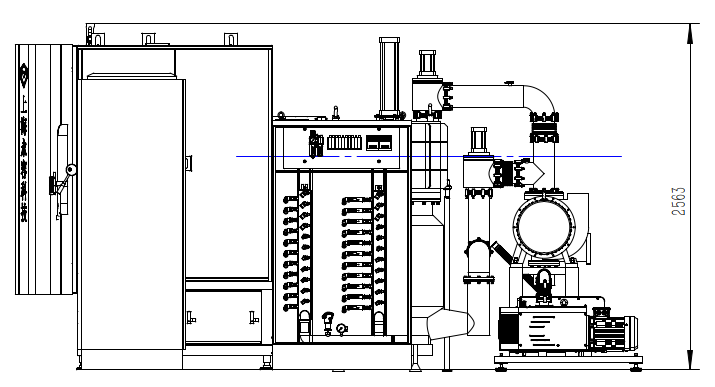

Vacuum Pumps: Mechanical pump, roots pump, holding pump and diffusion pump

Operation Control System: PLC controlled processing with Touch Screen HMI

Electrical Enclosures (mm) L x W x H : 1200 x 2000 x 600

Power Supply Cabinet : 600 x 2000 x 1000

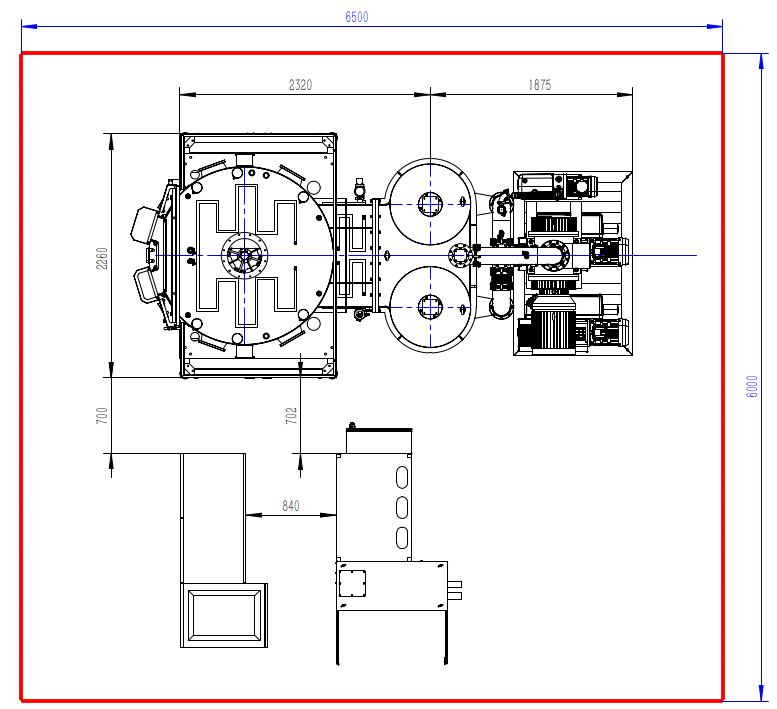

Machine configuration according to customer requirements, the fixture design and workshop layout plan supported by Royal Technology.

Layout

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.

Project Name: Low Temperature Arc Vapor Deposition Machine

Project Location: Shanghai, China

Project Built Time: 2021