The RTSP1200-PCB machine is a tailor-designed and made for cooper PCBs metallization by sputtering deposition technology.

Available sputtering targets: Nb, Ta, Au, Ag, Ti,Cr,Zr, Ni, Cu,

Graphite (C),SS316L etc

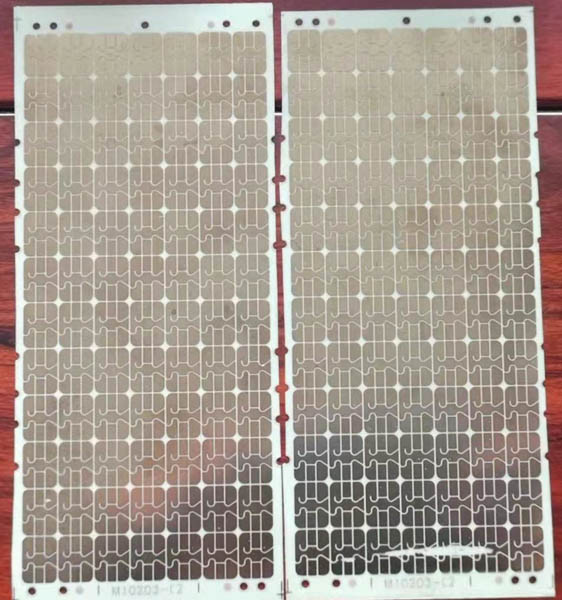

Everyone who is involved in PCB industry knows that PCBs which have copper finishes on the surface require a protective layer to protect it against oxidation and deterioration.

2 years ago, we received a request from our customer, they were looking for a coating solution which produces a fine gold and bronze colors on the copper PCBs which is used for 5G SIM card, social security cards and smart cards module. We spent 6 months in R&D, made over 20 experiments to finalize the proper coating processes. In March 2020, we delivered the machine to customer’s site with great satisfaction.

Prinited Circuit Boad, flexible electronics industry, 5G circuit microchip SIM card emblem isolated on white background

RTSP1200-PCB plating system can deposit the metals: Au gold, Ag silver, Cu copper conductive type of films; corrosion resistance type metals: Tantalum(Ta), Nickle (Ni), Chrome (Cr), SS316L etc. compounded films: carbon-based metal films, Nitride metal films.

PVD Gold Plating Advantages

Environmentally friendly process

Much lower production cost compared to conventional Gold electroplating

Excellent Life Span

Film thickness and uniformity are well controlled

Widely available, more options for end user

Key Features

Multiple deposition sources for fast deposition rate

Strong vacuum pumping system for a short cycle

Anode linear ion source to improve adhesion and high density of deposited films

6 units standard planar cathodes mounting flanges

Flexible coating processes applied

Modular structure design for fast exchange of cathodes and targets

Magnetron Sputtering System- Planar sputtering cathodes

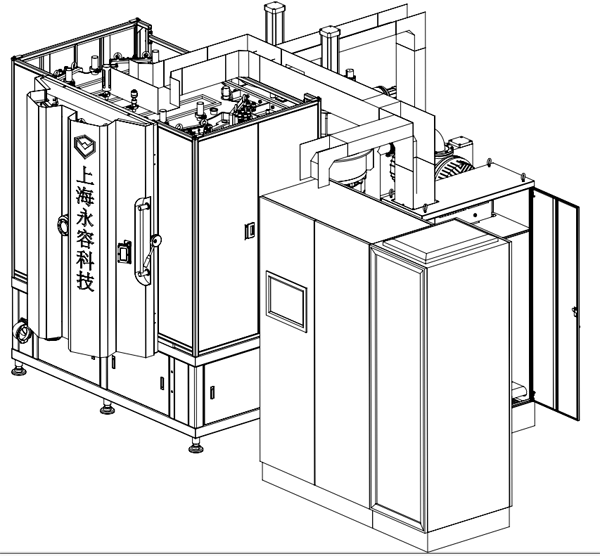

Model: RTSP1200-PCB

Chamber Material: SUS304

Chamber Size: Φ1200*1500mm (H)

Deposition Technology: Magnetron sputtering

Targets: Nb, Ta, Au, Ag, Ti,Cr,Zr, Ni, Cu, Graphite (C),SS316L etc

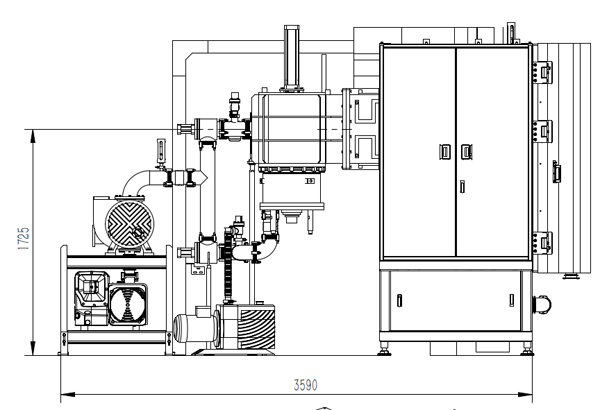

Vacuum Pumps: Mechanical Pump: 1x300m3/hr

Holding Pump:1x60m3/hr

Roots Pump: 1x300L/S

Turbo Molecular pump: 2x3500L/S

Gas System: MFC for reactive gas and inert working gas

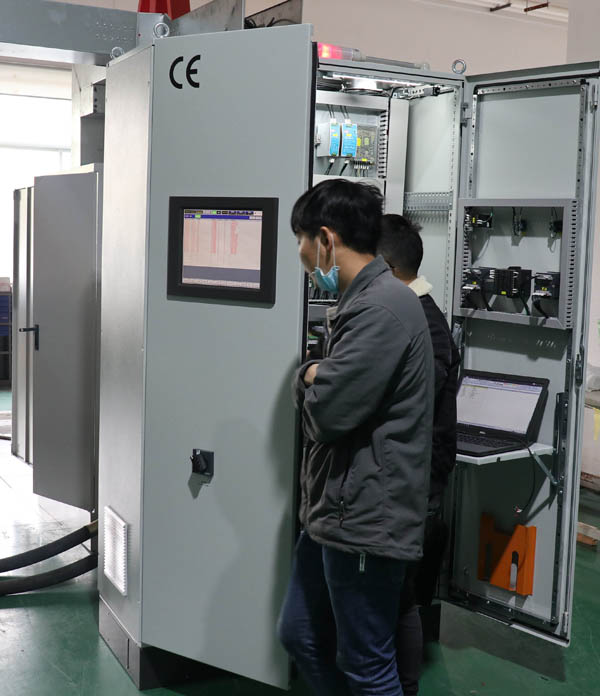

Protective System: HMI program with Multiple Self-Lock design

Operation & Control System: PLC + Touch Screen

Cooling System: Recycle Cooling water

Heating System: Heaters with PDI thermal couple

Max. Power Consumption 130KW Approx.

Average Power Consumption 70KW Approx.

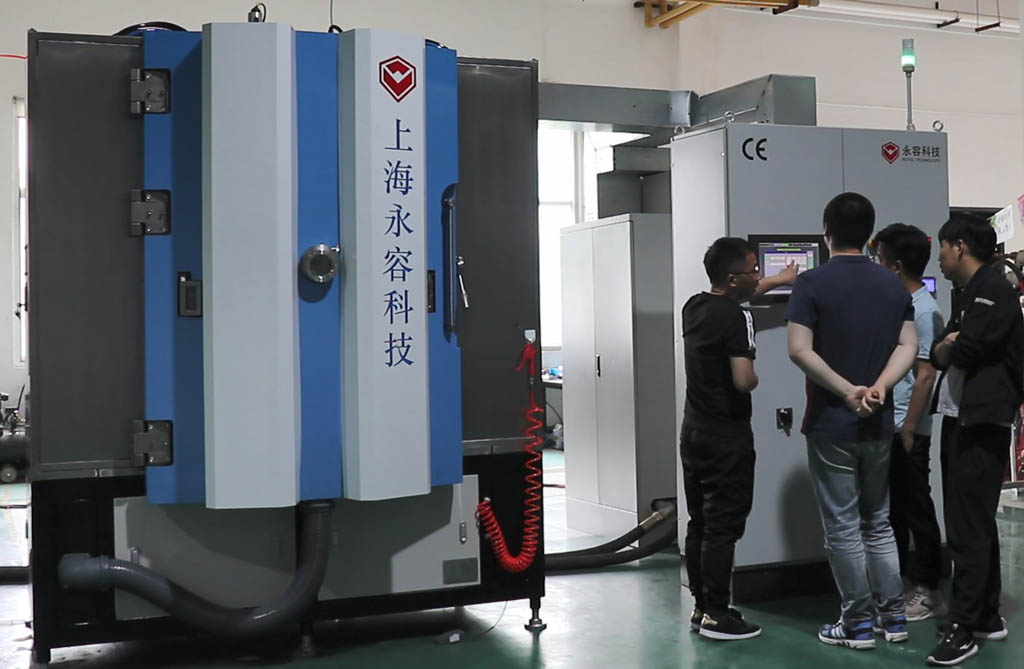

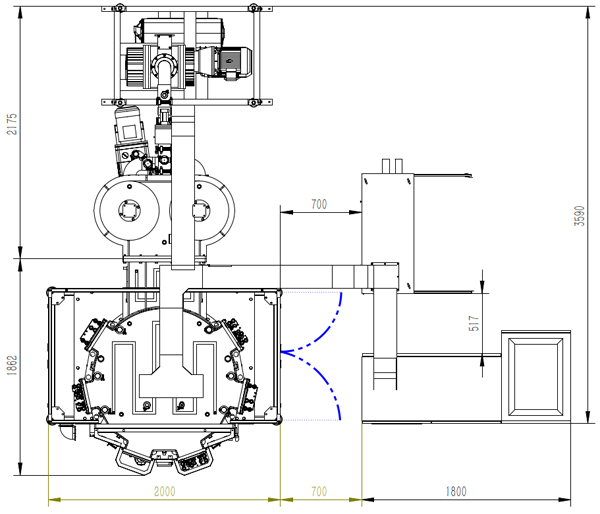

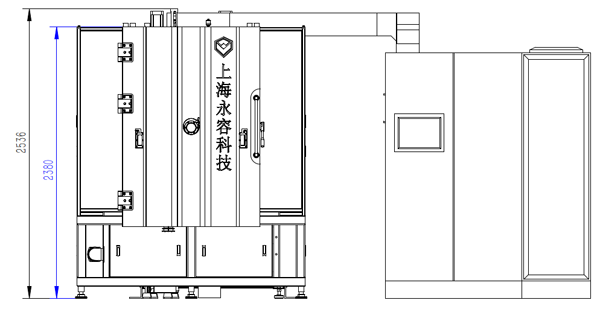

Layout

Machine Model: RT1200-PCB

Technology: Magnetron Sputtering Deposition/ Ion Beam

Built Time: August 2020

Location: China